Thin film solar cells made from perovskites have the potential to disrupt the solar energy sector thanks to their relatively low manufacturing cost, flexibility, and tunable band gap relative to silicon. However, researchers are struggling to solve reliability issues, and they also need to find a way to create devices at a viable commercial scale.

Many approaches use lead halides and require the inclusion of strong polar solvents with high boiling points and antisolvent quenching agents to control the crystallization process of perovskite thin films. This complicated mechanism can lead to defects in the thin films, causing the device to lose efficiency rapidly.

The use of non-halide lead sources, such as lead acetate, is a potential solution to this issue due to the fast perovskite crystallization process. However, to date, lead acetate has only been used to make methylammonium or cesium-based perovskites, which are relatively unstable, less efficient, and not suitable for real-world applications.

Now, members of Exciton Science, based at Monash University, have demonstrated a new pathway to create durable, efficient perovskite photovoltaics at an industrial scale through the first effective use of lead acetate as a precursor in making formamidinium-caesium perovskite solar cells.

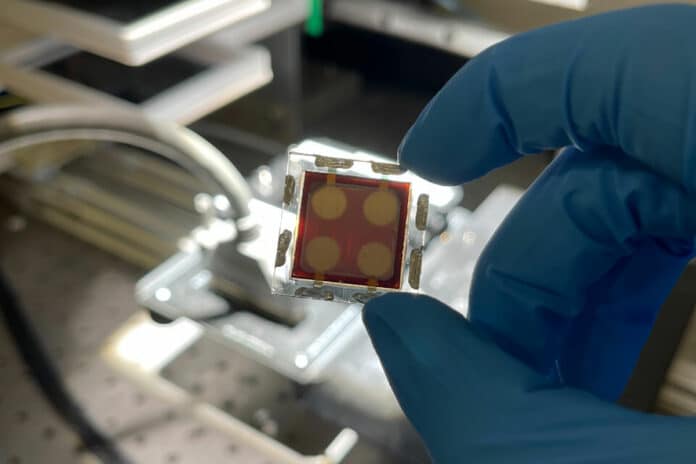

Researchers produced a high-quality large-area formamidinium-caesium mixed-cation perovskite films by blade-coating a lead acetate-based precursor formulation in an ambient laboratory environment, with the use of ammonium as a volatile cation to drive off acetate during annealing.

Using this method, the team was able to create perovskite solar cells with 21% efficiency, the best results ever recorded for a device made from a non-halide lead source.

In lab tests, a mini prototype solar panel featuring these cells achieved 18.8% efficiency. The large-area perovskite layer was fabricated in an ambient atmosphere and was made via a single-step blade coating, demonstrating its potential viability for industrial-scale manufacturing. The test devices also showed strong thermal stability, continuing to function with no efficiency loss after 3,300 hours running at 65 degrees Celcius.

“We’ve been able to use lead acetate in a one-step, spin-coating process to get the perfect, high-quality formamidinium-caesium perovskite thin film,” said first author Jie Zhao, a Ph.D. student at Monash University. “And because we don’t need an anti-solvent agent, we can do this via large-scale techniques, such as blade coating, which means it’s viable at industrial scale.”

“The vast majority of perovskite solar cell research uses lead halides, particularly lead iodide,” said Dr. Wenxin Mao, corresponding author, and Monash University colleague. “The lead iodide needs to be 99.99% pure, and it’s very expensive to synthesize cells using lead iodide. We’re the first group to make highly stable formamidinium-cesium perovskite solar cells using lead acetate rather than lead iodide.”

The researchers hope their work on the fundamental chemistry governing precursor behavior can encourage a greater focus on scalable synthesis and fabrication methods of metal halide perovskite devices.

Journal reference:

- Jie Zhao, Sebastian O. Fürer, David P. McMeekin, Qingdong Lin, Pin Lv, Jisheng Ma, Wen Liang Tan, Chao Wang, Boer Tan, Anthony S. R. Chesman, Huiyu Yin, Andrew D. Scully, Christopher R. McNeill, Wenxin Mao, Jianfeng Lu, Yi-Bing Chenghi, and Udo Bach. Efficient and stable formamidinium–caesium perovskite solar cells and modules from lead acetate-based precursors. Energy and Environmental Science, 2022; DOI: 10.1039/D2EE01634F