The European research consortium EUROfusion has announced the start of a five-year conceptual design phase for its demonstration fusion power plant DEMO, capable of net electricity production, shortly after the middle of the century in its Roadmap to Fusion Energy.

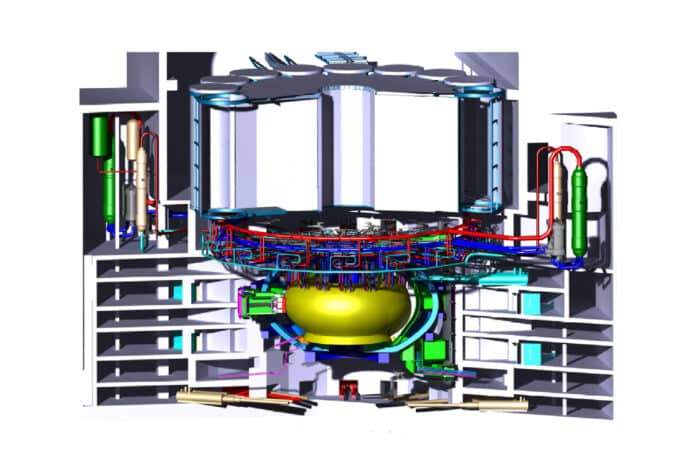

The first-of-its-kind facility represents the next technological step after the global ITER fusion experiment. It aims to demonstrate the net production of 300 to 500 megawatt of electricity generated by nuclear fusion, clean and safe energy, as well as essential technologies such as remote maintenance and tritium breeding. The tritium breeding technology will allow operators to produce the tritium fusion fuel on-site is a crucial requirement not just for DEMO but also for any future fusion power device to follow ITER.

Fusion is the process that powers stars like our Sun and promises an inherently safe and nearly unlimited long-term clean energy source here on Earth. Fusion energy will generate immense amounts of energy from just a few grams of the abundant fuels found all over the world.

Before reaching the conceptual phase, the DEMO team presented the result of their Pre-Concept Design Phase (2014-2020). This covered several areas such as power exhaust, tritium breeding, extraction of high-grade heat from the breeding blanket, remote maintenance for in-vessel components, robust magnet designs, qualified structural and plasma-facing component materials, as well as nuclear safety and integration.

“The DEMO design and R&D activities in Europe are benefitting largely from experience gained from the design, licensing, and construction of ITER,” the EUROfusion researchers wrote in the statement. If the DEMO Engineering Design efforts start too long after ITER is delivered, a highly skilled and experienced workforce will be lost to other industries, with an unavoidable brain drain and loss of lessons learned.

“That is why we focus on attracting talented, enthusiastic people to the field, especially engineers who have a systemic view of the entire plant.”