Developing a lightweight material with simultaneous high strength and ductility has been regarded as a long-desired goal in the field of structural materials. But these properties are generally mutually exclusive.

Researchers at the City University of Hong Kong (CityU) recently discovered a low-cost, direct method to turn commonly used 3D printable polymers into lightweight, ultra-tough, biocompatible hybrid carbon microlattices. These microlattices can be in any shape or size and are 100 times stronger than regular polymers.

Researchers believe that this innovative approach can be utilized to develop complex 3D parts with customized mechanical properties for a wide range of applications, such as coronary stents and bio-implants.

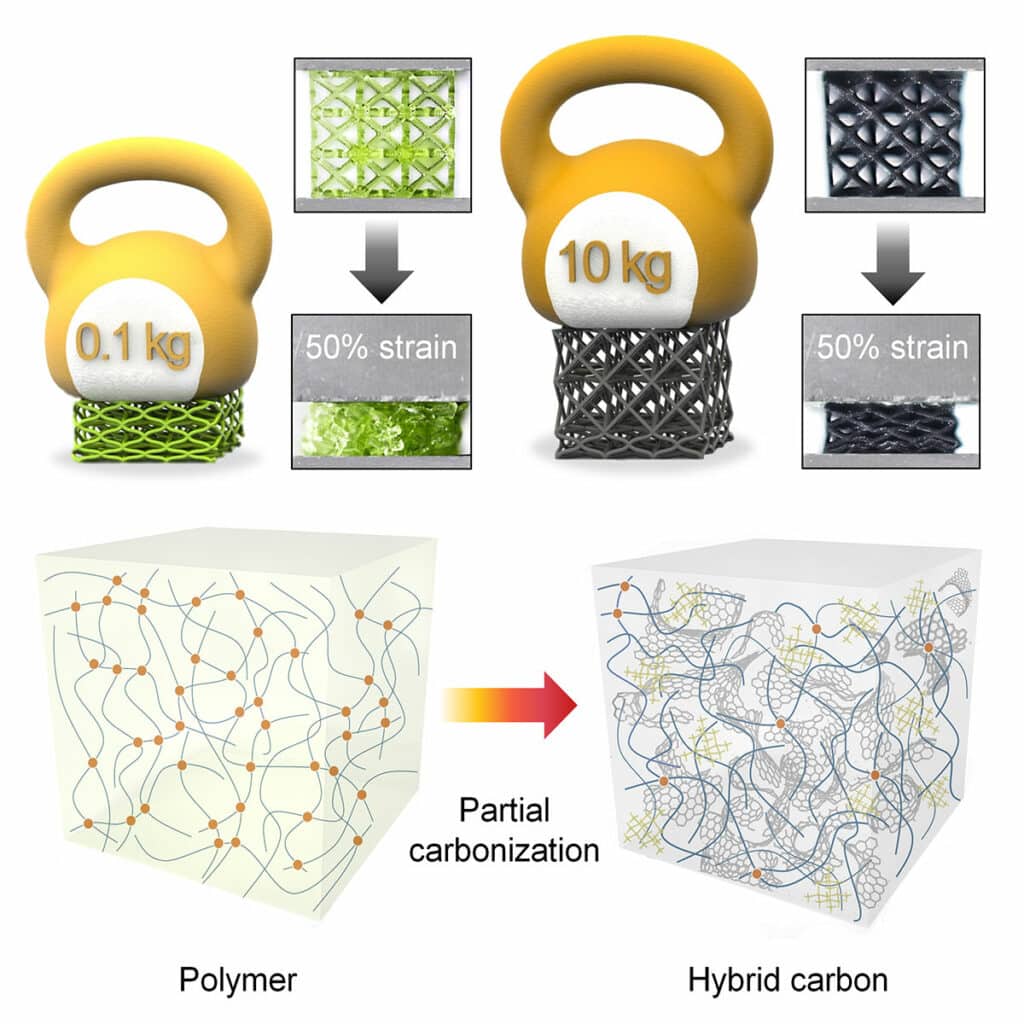

So far, the most effective approach for increasing the strength of these 3D printable polymer lattices is pyrolysis. But this process deprives the original polymer lattice of almost all its deformability and produces an extremely brittle material.

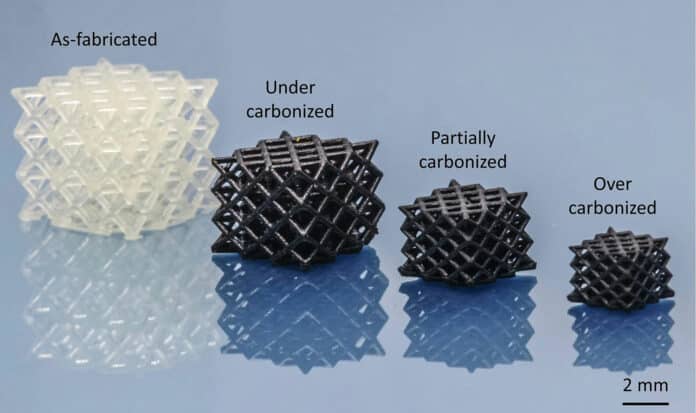

Researchers discovered a “magic-like” condition in the pyrolysis of the 3D-printed photopolymer microlattices, which resulted in a 100-fold increase in strength and doubled the ductility of the original material. They found that by carefully controlling the heating rate, temperature, duration, and gas environment, it is possible to simultaneously enhance the stiffness, strength, and ductility of a 3D-printed polymer microlattice drastically in a single step.

To obtain optimal strength and ductility, the ratio of polymer to carbon fragments is also crucial. The material lacks strength if there are too many carbon fragments and becomes brittle, and if there are too few. During the experiments, the team successfully created an optimally carbonized polymer lattice.

The team also found that these “hybrid carbon” microlattices showed improved biocompatibility compared to the original polymer. Through cytotoxicity and cell behavior monitoring experiments, they proved that the cells cultured on the hybrid carbon microlattices were more viable than cells seeded on the polymer microlattices.

“Our work provides a low-cost, simple, and scalable route for making lightweight, strong and ductile mechanical metamaterials with virtually any geometry,” said Professor Lu Yang, who led the research.

He envisions that the newly invented approach can be applied to other types of functional polymers and that the geometrical flexibility of these architected hybrid-carbon metamaterials will allow their mechanical properties to be tailored for a wide range of applications, such as biomedical implants, mechanically robust scaffolds for micro-robots, energy harvesting and storage devices.

Journal reference:

- James Utama Surjadi, Yongsen Zhou, Siping Huang, Liqiang Wang, Maoyuan Li, Sufeng Fan, Xiaocui Li, Jingzhuo Zhou, Raymond H.W. Lam, Zuankai Wang, Yang Lu. Lightweight, ultra-tough, 3D-architected hybrid carbon microlattices. Matter, 2022; DOI: 10.1016/j.matt.2022.08.010