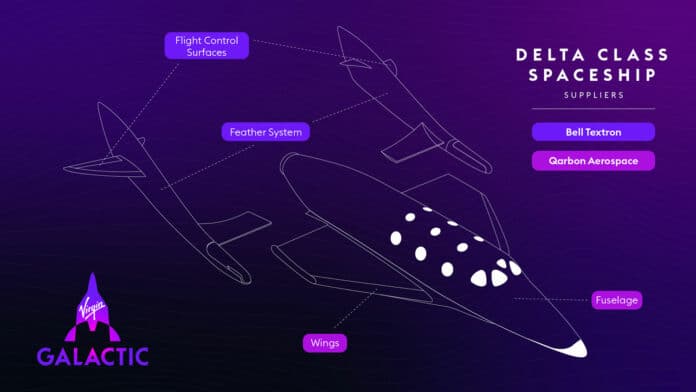

An American aerospace and space travel company, Virgin Galactic, has entered into an agreement with Bell Textron and Qarbon Aerospace to manufacture key subassemblies for the Company’s new Delta class spaceships. The production-model vehicle is designed to fly weekly with six passengers per ship.

Bell will supply the unique feathering system and flight control surfaces, while Qarbon Aerospace will produce the fuselage and wing. Both these companies were selected following a competitive RFP process based on their ability to meet Virgin Galactic’s unique design and fabrication requirements.

Virgin Galactic will be in charge of the overall system architecture, design authority for all components, and the final assembly, integration, checkout, and acceptance testing of the vehicles.

“The Delta class spaceships are an evolution of our distinctive flight system, designed for improved manufacturability, maintenance, and flight rate capability,” said Virgin Galactic CEO Michael Colglazier. “Bell and Qarbon Aerospace are established partners who bring know-how, ideas, and resources that will enable us to produce up to six new Delta Class ships per year. Together with Aurora Flight Sciences, who is producing our next-gen motherships, we now have the primary suppliers in place to propel the production of our spaceline fleet at scale.”

The Company says the design work on the six-passenger spaceship will begin immediately, with vehicle production targeted to commence in 2023 at Virgin Galactic’s new facility in Arizona. The first Delta class spaceships are expected to commence revenue-generating payload flights in late 2025, progressing to private astronaut flights in 2026.