Permanent magnets play a critical role in some of the world’s largest wind turbines. Rare earth magnets, like neodymium magnets, are used in some of the largest wind turbines in the world to provide efficient electricity generation.

Considering the growing rate of global wind power and the overall benefits of the permanent magnet synchronous generator (PMSG) wind turbines, the future demand for high-performing neodymium magnets and their constituent elements is likely to increase. Future deployment of wind power generation may be affected by potential disruptions in supply and price rises of critical rare earth elements.

Motivated by the need to eliminate expensive rare-earth magnets in utility-scale direct-drive wind turbines, Sandia National Laboratories researchers developed a fundamentally new type of rotary electrical contact. Sandia is now ready to partner with the renewable energy industry to develop the next generation of direct-drive wind turbines.

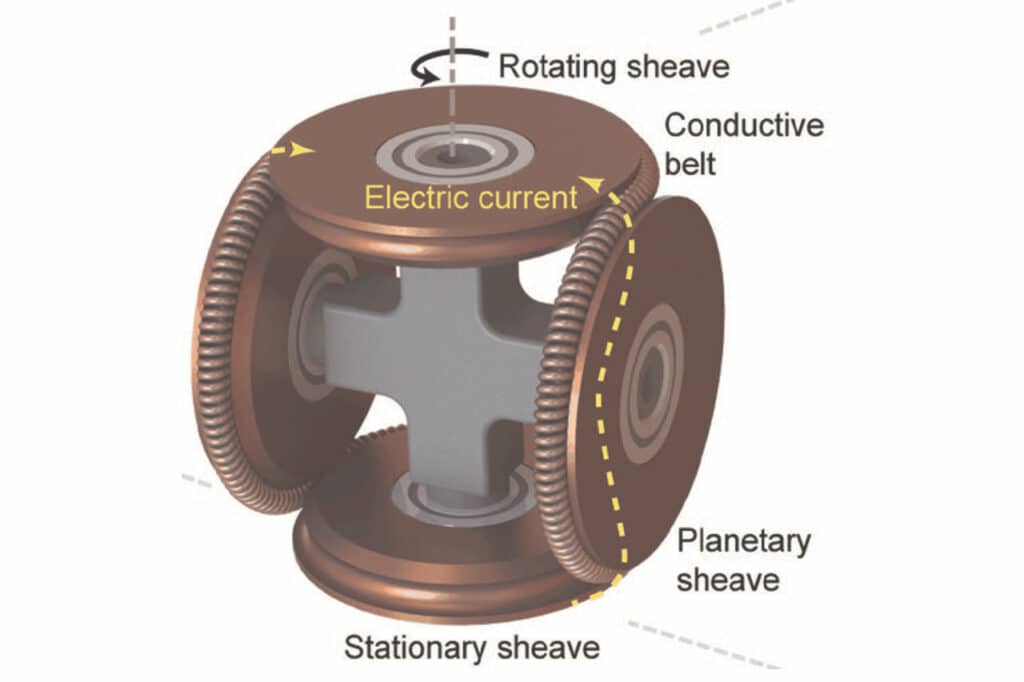

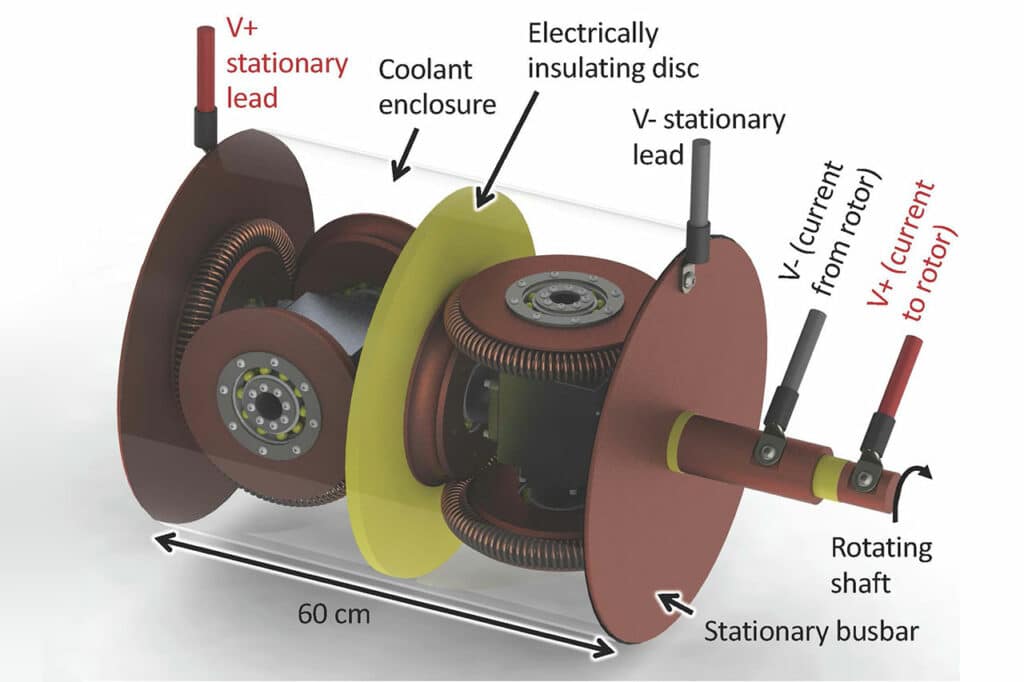

Sandia’s Twistact technology is a novel approach to transmitting electrical current between a stationary and rotating frame or between two rotating assemblies having different speeds or rotational directions, ideal for application in wind turbines. The innovative Twistact uses a pure-rolling-contact device to transmit electrical current along an ultra-low-resistance path. The technology proves beneficial in lowering costs, improving sustainability, and reducing maintenance.

Most of the current utility-scale wind turbines are dependent on rare-earth magnets. These materials come at a high initial cost and are vulnerable to supply chain uncertainties. For example, there was a rare-earth materials supply chain crisis in 2011 that caused the price of neodymium and dysprosium, the two rare-earth elements widely used for such magnets, to skyrocket. Such an event has the potential to block the growth of the wind industry.

Sandia’s Twistact technology addresses two physical degradation processes common to high-maintenance brush or ship ring assemblies – sliding contact and electrical arcing. These factors reduce the performance of the traditional rotary electrical contacts and lead to shorter operating lifecycles and high maintenance and replacement costs. Twistact has been proven through laboratory testing to be capable of operating over the full 30-year service time of a multimegawatt turbine without maintenance or replacement.

Other potential applications for the technology include synchronous motors and generators, electrified railways, and radar towers. Twistact could also be used in replacing brush or ship rings in existing applications.

Sandia is now exploring opportunities to partner with generator manufacturers and others in the renewable energy industry to assist with the transfer of Twistact technology into next-generation direct-drive wind turbines. Further, Sandia is open to partnering on the development of high-RPM Twistact technology for applications such as electric vehicles or doubly fed induction generators.