Waste-heat electricity generation using high-efficiency solid-state conversion technology can significantly reduce our reliance on fossil fuels. Thermoelectric generators (TEGs) can directly convert waste heat into clean electricity.

Researchers in the Department of Materials Science and Engineering at Penn State have been working to improve the performance of thermoelectric generators. When the devices are placed near a heat source, charge carriers, like electrons, moving from the hot side to the cold side, produce an electric current.

Now, the researchers have developed a new method for creating functionally graded materials that can push the conversion efficiency of these devices up to 15.2% for a single-leg device with a temperature change of 670 degrees Kelvin. This is the highest efficiency that has been recorded so far using this kind of thermoelectric technology, according to researchers.

Traditional thermoelectric generators have segmented designs to optimize performance on the higher- and lower-temperature sides of the device. These are often different types of materials that must be created separately and joined together by brazing or soldering. But this creates a heterogeneous interface that can reduce the device’s efficiency, the scientists said.

The new method eliminates the need for that interface because the higher- and lower-temperature side materials are created together in a single step. “The basic idea is to integrate two or more layers using the same material family but with a slight difference in chemical compositions,” said Wenjie Li, assistant research professor in the Department of Materials Science and Engineering at Penn State. “And by doing so, we can create the functionally graded materials in one step, and we don’t need any brazing or soldering techniques to join them, eliminating the heterogeneous interface.”

To create the materials, the researchers used a process called spark-plasma sintering, the technique that uses electric current and pressure to compress fine powders into a solid mass of material. The process allows scientists to create functionally graded materials by placing powders one underneath another and to tailor those layers by adding dopants or ingredients that can change a material’s properties.

This enabled the team to optimize the chemical compositions of the higher- and lower-temperature sides while using materials from the same family that can be sintered at similar temperatures in one step. And because the materials are from the same family, they have closely matched thermal expansion and other mechanical properties. This means the devices will have long operational life compared to conventional segmented devices, the scientists said.

“One requirement to achieve maximum conversion efficiency is that the optimum current going through the entire device is the same for the high-temperature and low-temperature side,” Li said. “But in the conventional design, since we used different materials systems, the electrical resistivity of these two materials may be significantly different.”

The current study only applies to the p-type material, and the scientists said further work to apply this to the n-type could result in additional increases in efficiency. Future work will focus on creating additional layers of the leg, each optimized for a different temperature range, using the one-step sintering approach, which could also further improve efficiency.

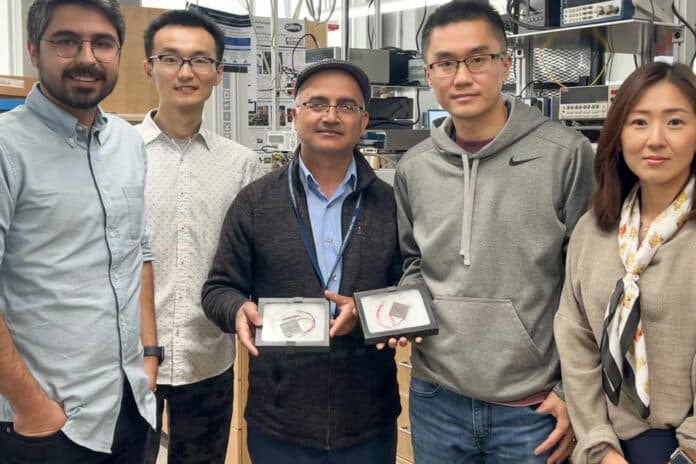

“What we demonstrated by generating 15% conversion efficiency is now this technology is very much competitive with other power generation technologies at the smallest scale — like small diesel generators or even solar panels,” said Bed Poudel, research professor in the Department of Materials Science and Engineering at Penn State. “We show heat energy can be converted into electricity in a competitive way with those technologies.”

Journal reference:

- Wenjie Li, Bed Poudel, Ravi Anant Kishore, Amin Nozariasbmarz, Na Liu, Yu Zhang, Shashank Priya. Toward High Conversion Efficiency of Thermoelectric Modules through Synergistical Optimization of Layered Materials. Advanced Materials, 2023; DOI: 10.1002/adma.202210407