The waters off the coast of New England have become noisier in the last year as the nation’s first-ever large-scale offshore wind farms began pile-driving steel turbines into the ocean floor. This could have negative impacts on marine life, especially the whales, dolphins, and the endangered species that inhabit the northern Atlantic.

To mitigate the impact on marine life, developers have come up with a solution: blowing bubbles.

“Pile driving in the ocean is very, very noisy,” said Richard Hine, whose maritime company ThayerMahan Offshore is the first U.S. firm to pilot “bubble curtains” for wind turbine construction. The walls of air bubbles help absorb sound energy. “You can knock out about 80 to 90 percent of the acoustic energy and get it below levels where they’re harmful to marine mammals,” Hine said.

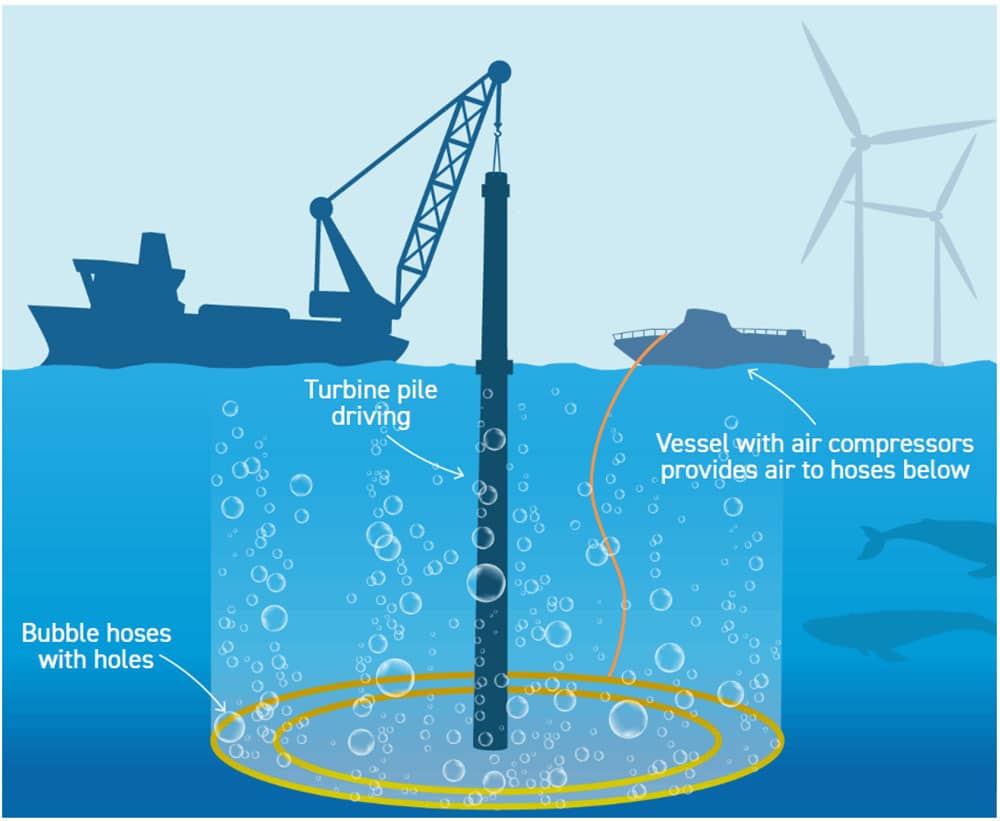

As the offshore wind industry expands rapidly off the coasts of the United States, it is looking for ways to reduce its potential impacts on the marine environment. One of these methods is the use of bubble curtains, which are one way the rapidly expanding offshore wind industry is trying to mitigate its potential harms as it grows off the nation’s coasts. The devices create a wall of bubbles around the construction site to dampen the noise and vibrations that could harm marine life.

This is especially important in light of the recent whale deaths on the Eastern Seaboard, which have raised concerns about the effects of offshore wind development on these endangered animals. While experts have attributed these deaths to ship collisions, fishing entanglements, and a growing humpback whale population, the offshore wind industry faced criticism from Republican lawmakers and beach homeowners. These harsh accusations have put pressure on offshore wind developers to demonstrate their commitment to environmental protection and mitigation.

With more offshore wind projects planned for the near future, the use of bubble curtains and other mitigation measures could help the industry avoid further controversy and ensure its long-term sustainability.

The Biden administration has set ambitious goals for offshore wind farms in the U.S. With the aim of approving 16 offshore wind farms by 2025; the government hopes to power 10 million homes with wind turbines by 2030, which is a significant step towards meeting national and state climate goals. The construction of the first two large-scale offshore wind farms, Vineyard Wind and South Fork Wind, is already underway off the coasts of Rhode Island and Massachusetts. These projects use double bubble curtains during turbine installation to reduce the sound.

The process of creating effective bubble curtains involves the use of steel-encased, perforated rubber hoses that are sunk to the seafloor in two concentric rings around a monopile. As sound waves pulse out during pile driving, that sound energy must travel through the two walls of air, greatly reducing their impact.

ThayerMahan vessels carry a suite of powerful air compressors to create bubbles that also help to mitigate a lot of the sound by creating large density changes, like from water to air.

At Vineyard, the crew of around 30 people, including union deck crews based in New England, start preparing about 30 minutes before pile driving begins to create suitable air barriers. The vessels also monitor the sound levels throughout the pile driving to gauge how much sound is getting through the curtain.

“Whales are a sensitive topic for the wind industry,” Hine said. “It’s a key part of safely installing wind turbines and doing it in an environmentally sensitive way where you’re not killing mammals and fish.”

The bubble curtain technology is also somewhat effective for high-frequency sound mitigation, helping mammals like porpoises and dolphins.