A team of researchers led by Stanford University has developed a new type of rechargeable battery that, they say, can store up to six times more charge than ones that are currently commercially available.

The new high-performance rechargeable battery could enable cellphones to be charged only once a week instead of daily. Also, the new battery chemistry might be used to enable electric vehicles to travel six times farther without a recharge.

The new alkali metal-chlorine battery relies on the back-and-forth chemical conversion of sodium chloride (Na/Cl2) or lithium chloride (Li/Cl2) to chlorine. Electrons travel from one side of a rechargeable battery to the other as the battery discharges and travel the opposite direction when the battery is recharging.

The reason no one has yet created a high-performance, rechargeable sodium-chloride or lithium-chlorine battery is because chlorine is too reactive and difficult to convert back to chloride with high efficiency. In the few cases where researchers were able to achieve a certain degree of rechargeability, the battery’s performance turned out to be too poor for practical uses.

However, the team didn’t begin with the goal of creating rechargeable sodium and lithium-chlorine batteries at all. Rather the goal was to improve their existing battery technologies using thionyl chloride, which is one of the main ingredients of lithium-thionyl chloride batteries – a popular type of single-use battery first invented in the 1970s.

In one of their early experiments involving chlorine and sodium chloride, researchers discovered the conversion of one chemical to another was stabilized, resulting in rechargeability. It took about a year for the team to really realize what was going on and the next several years to finally elucidate the mechanism of this reversible chemistry and seek ways to make it more efficient by experimenting with many different materials for the battery’s positive electrode.

Eventually, the team discovered a carbon material had a nanosphere structure filled with many ultra-tiny pores. In practical terms, these hollow spheres work like a sponge, absorbing large amounts of the sensitive chlorine molecules and storing them for later conversion to salt inside the micropores.

“The chlorine molecule is being trapped and protected in the tiny pores of the carbon nanospheres when the battery is charged,” a lead researcher Guanzhou Zhu explained. “Then, when the battery needs to be drained or discharged, we can discharge the battery and convert chlorine to make NaCl – table salt – and repeat this process over many cycles. We can cycle up to 200 times currently, and there’s still room for improvement.“

So far, the team has achieved 1,200 milliamperes-hour per gram of positive electrode material, which is no less than six times greater than the 200 milliamperes-hours achieved by today’s lithium-ion batteries.

Researchers envision their batteries being used in the future in situations where frequent recharging is not practical or desirable, such as in satellites or remote sensors – many small satellites have become space junk due to dead batteries.

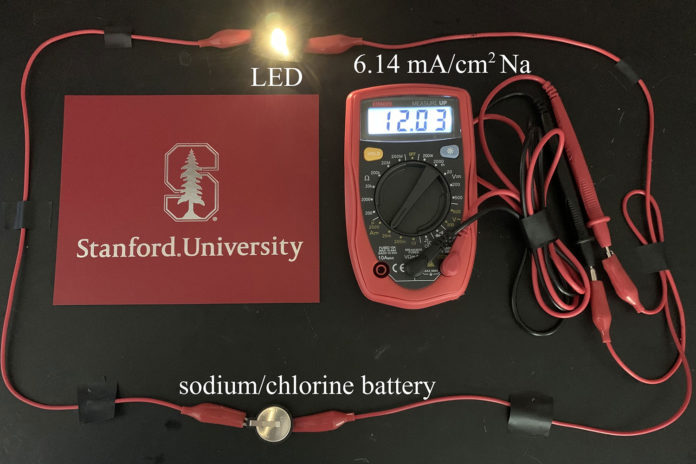

For now, the working prototype that the team has developed – equivalent to a button-type battery – may already be suitable for use in small devices such as hearing aids or remote controls. For consumer electronics or electric vehicles, much more work remains to engineer the battery structure, increase the energy density, scale up the batteries and increase the number of cycles.