Japanese shipping company Mitsui O.S.K. Lines and Norway-based EnviroNor have signed a memorandum of understanding to discuss collaboration on a Floating Desalination Vessel (FDV) and have begun collaboration toward commercialization.

The project will combine MOL’s extensive experience in building, owning, and operating ships over many years with EnviroNor’s expertise in shipping and desalination. The two companies aim to build FDVs and capture business opportunities as a means of providing new fast-track solutions all over the world, where water shortages are a current and rapidly growing challenge.

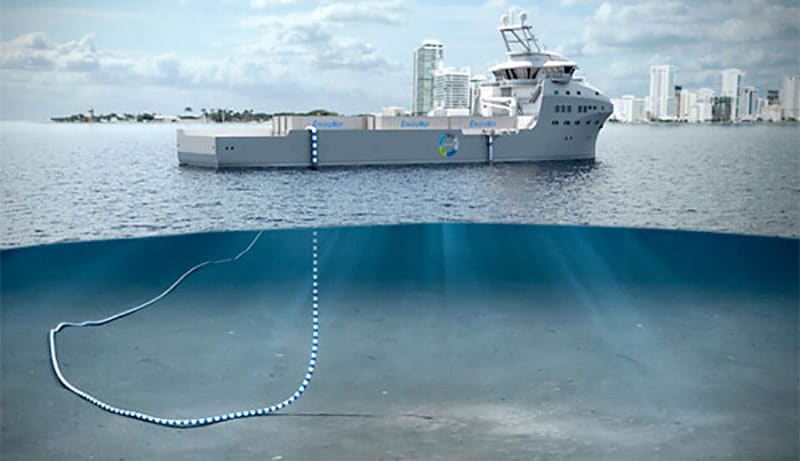

Tankers of various sizes will be converted into Floating Desalination Vessels equipped with seawater desalination equipment and clean energy sources. Through reverse osmosis (RO) membranes, the FDV will remove impurities other than water, producing fresh water (drinking water) and supplying it to shore.

Compared to the seawater desalination plant on land, FDVs do not require the acquisition of land and are built by converting a used ship, so it offers advantages such as the ability to start water supply in a short time.

The commercialization of a floating desalination vessel was suggested through the Group employee proposal system “MOL Incubation Bridge.” The system was introduced in September 2019 and has fostered out-of-the-box thinking in the creation of new businesses and services in the changing business environment.

This project not only addresses the huge issue of freshwater scarcity in certain areas but is also sustainable. It uses fewer resources for desalination compared to land-based desalination plants and is also much more flexible. The process can be completed much faster and more effectively by converting oil tankers instead of building new vessels from scratch.