Over the last decade, perovskite solar cells, made from metal halide perovskite materials, have shown promise to make cheaper and potentially more efficient solar cells than silicon. But, whilst perovskite solar cells can now compete in terms of efficiency with more established silicon-based solar cells, a key challenge that remains unaddressed is their chemical instability. Perovskite materials are very sensitive to moisture, oxygen, and even light, meaning they can degrade rapidly in the air.

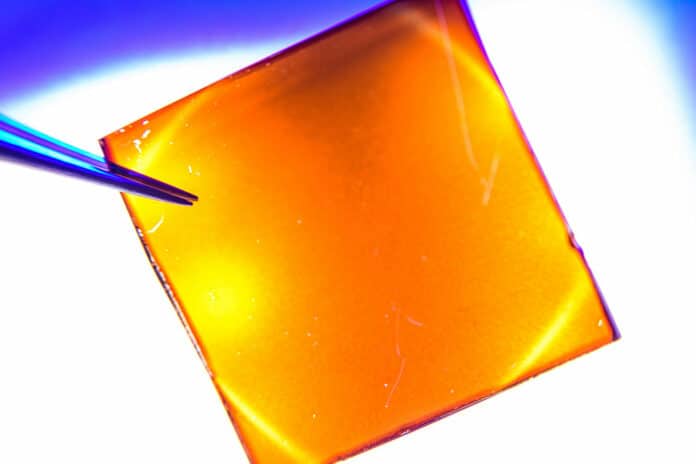

Now, Rice University engineers say they’ve solved this long-standing problem in making stable, efficient solar panels out of halide perovskites. They reported in the paper in Science their success at building thin 3D/2D solar cells with high energy conversion efficiency. Researchers described the right solvent design to apply a 2D top layer of desired composition and thickness without destroying the 3D bottom one (or vice versa).

Aditya Mohite, a chemical and biomolecular engineer, said 2D perovskite cells are stable but less efficient at converting sunlight. On the other hand, 3D perovskites are more efficient but less stable. Combining these two types incorporates the best features of both. This is really good for flexible, bifacial cells where light comes in from both sides and also for back-contacted cells. The 2D perovskites absorb blue and visible photons, and the 3D side absorbs near-infrared.

“This leads to very high efficiencies because now, for the first time in the field, we are able to create layers with tremendous control,” Mohite said. “It allows us to control the flow of charge and energy for not only solar cells but also optoelectronic devices and LEDs.”

The new advance largely removes the last major roadblock to commercial production. “This is significant at multiple levels,” Mohite said. “One is that it’s fundamentally challenging to make a solution-processed bilayer when both layers are the same material. The problem is they both dissolve in the same solvents. When you put a 2D layer on top of a 3D layer, the solvent destroys the underlying layer. But our new method resolves this.”

Solution processing is widely used in industry and incorporates a range of techniques to deposit material on a surface in a liquid. When the liquid evaporates, the pure coating remains.

Mohite and team looked at two important properties of the solvent itself – its dielectric constant and Gutmann donor number. The dielectric constant is the ratio of the electric permeability of the material to its free space. This determines how well a solvent can dissolve an ionic compound. The donor number is a measure of the electron-donating capability of the solvent molecules.

Researchers found there were about four solvents that could dissolve perovskites and spin-coat them without destroying the 3D layer. The efficiency of test cells exposed to the lab equivalent of 100% sunlight for more than 2,000 hours does not degrade by even 1%. The solar cells maintained a peak PCE of 24.5% under continuous light at 55°C and 65% relative humidity. Not counting a glass substrate, the cells were about 1 micron thick.

Mohite said their discovery should be compatible with roll-to-roll manufacturing that typically produces 30 meters of solar cells per minute.

Journal reference:

- Siraj Sidhik, Yafei Wang, Michael De Siena, Reza Asadpour, Andrew J. Torma, Tanguy Terlier, Kevin Ho, Wenbin Li, Ananad B. Puthirath, Xinting Shuai, Ayush Agrawal, Boubacar Traore, Matthew Jones, Rajiv Giridharagopal, Pulickel M. Ajayan, Joseph Strzalka, David S. Ginger, Claudine Katan, Muhammad Ashraful Alam, Jacky Even, Mercouri G. Kanatzidis, and Aditya D. Mohite. Deterministic fabrication of 3D/2D perovskite bilayer stacks for durable and efficient solar cells. Science, 2022; DOI: 10.1126/science.abq7652