Energy is a basic need in human life, and people are consuming more and more energy for doing their activities in daily life. The energy efficiency of buildings could be strongly improved by enabling building materials to convert their occupants’ mechanical energy directly into useful electricity.

In a potential energy-efficient breakthrough for interior design, the ETH Zurich researchers have shown wooden floors can harvest enough energy by just walking on them to power LED lightbulbs and small electronics.

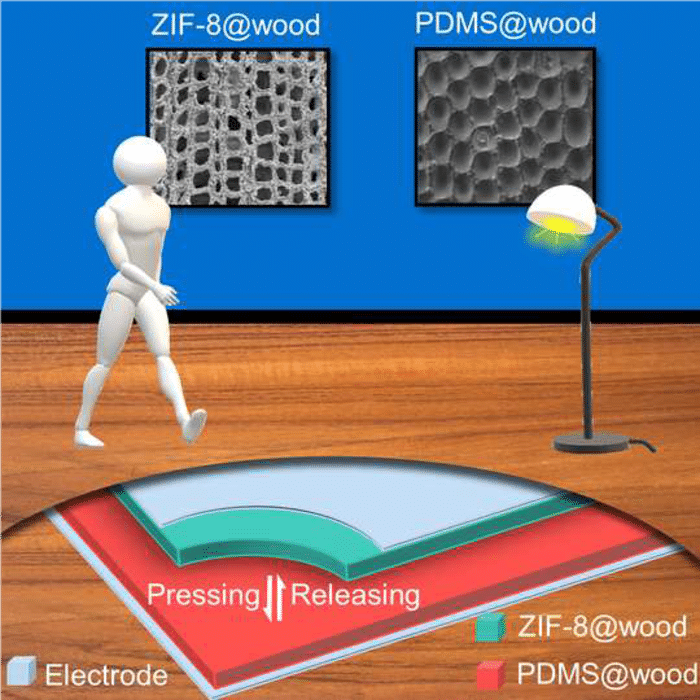

Researchers have developed functionalized wood triboelectric nanogenerators that generate electricity from our footfalls. The team transformed wood into a nanogenerator by sandwiching two pieces of functionalized wood between electrodes. They also improved the wood used in their nanogenerator with a combination of a silicone coating and embedded nanocrystals.

It’s footfalls that cause the triboelectric effect, making wood pieces electrically charged through periodic contacts and separations when strapped on. During the triboelectric effect, the electrons can transfer from one object to another, generating electricity.

However, there is one problem in making a nanogenerator out of wood. “Wood is basically triboneutral,” says senior author Guido Panzarasa. “It means that wood has no real tendency to acquire or to lose electrons.” This limits the material’s ability to generate electricity, “so the challenge is making wood that is able to attract and lose electrons.“

To overcome this problem, the team coated one piece of the wood with silicone that readily gains electrons upon contact and embedded the other piece with metal ions and organic molecules that give it a higher tendency to lose electrons. The team tested this treatment on different species of woodcut in different directions and found that a triboelectric nanogenerator made with radially cut spruce performed the best. The treatments boosted the triboelectric nanogenerator’s performance, generated 80 times more electricity than natural wood, and provided a stable output for up to 1,500 cycles.

According to the researchers, the wood floor prototype with a surface area slightly smaller than a piece of paper could generate enough energy to drive household LED lamps and small electronic devices such as calculators.

“Our focus was to demonstrate the possibility of modifying wood with relatively environmentally friendly procedures to make it triboelectric,” says Panzarasa. “Spruce is cheap and available and has favorable mechanical properties. The functionalization approach is quite simple, and it can be scalable on an industrial level. It’s only a matter of engineering.“

In addition to being efficient, sustainable, and scalable, the newly developed nanogenerator also preserves the features that make the wood useful for interior design. Next, the team plans to further optimize the nanogenerator with chemical coatings that are more eco-friendly and easier to implement.

“Even though we initially focused on basic research, eventually, the research that we do should lead to applications in the real world,” says Panzarasa. “The ultimate goal is to understand the potentialities of wood beyond those already known and to enable wood with new properties for future sustainable smart buildings.“