The growth of the photovoltaic sector has stood out among renewable sources of energy due to technological innovations that have brought about cost reductions. The average panel of approximately 2 square meters can use up to 20 grams of silver, which is the world’s most efficient and cost-effective electrical and thermal conductor.

A research project at the University of Virginia aims to prove there’s a better way to extract the silver from old solar panels in order to put the valuable material back into new solar panels, biomedical devices, and other productive uses.

The majority of photovoltaic solar cell manufacturing uses thick film screen print metallization with silver-containing paste to produce solar cells. Pastes mainly used include rear silver, rear aluminum, and front silver. The manufacturers then use the screen printing process and high temperatures to make the thin silver lines that can be seen on the outside of the panels’ photovoltaic cells.

For the recovery of silver, researchers will use a new method called laser ablation on the PV cells, converting the silver electrical contact material into nanoparticles. After extraction, the silver will need no further refinement before it can be used in new silicon modules. The recovered silver could also be purified for other uses.

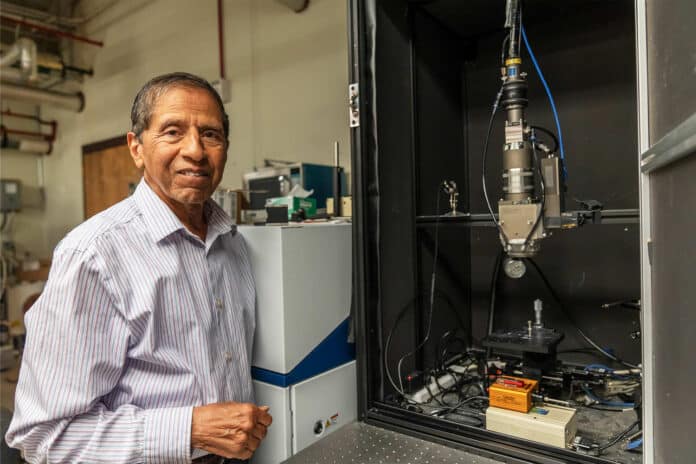

UVA engineering professor Mool Gupta is the principal investigator for the project, which received a one-year, $250,000 Department of Energy grant in June. The project is part of an overall $6 million DOE Solar Energy Technologies Office effort to seed small, innovative projects in photovoltaics and solar-thermal technologies.

The patent-pending technology will be a greener approach than the existing method of silver extraction, which uses nitric acid to recover silver from old or broken silicon solar cells – the technique that can be environmentally harmful and inefficient. Professor Gupta says if their process can be perfected, solar panel manufacturers and recycling companies would have an incentive to take back old panels and get greater use out of them, to benefit consumers and the environment.

Solar panels have a useful life of up to 25 years. Manufacturers don’t tend to refurbish the panels after that because of costs. The main avenue for repurposing old panels, then, has been at glass recycling facilities, where the glass and sometimes the frames are recovered before the other elements are burned or otherwise disposed of. By 2050, solar-module waste is expected to reach 78 million tons.

“It is hard to compete with the low-cost, environmentally unfriendly landfill approach,” Gupta said. But he and his team are confident the new technology can.

“Professor Gupta’s advances in research and innovative use of laser ablation represent a key step forward in realizing clean, sustainable, and inexpensive energy sources for the future,” Professor Scott Acton, chair of the Electrical and Computer Engineering Department, said.

meta: Researchers use laser ablation to extract the silver from old solar panels to put the valuable material back into new solar panels and biomedical devices.