Approximately 400 million tons of plastic waste is generated each year, largely as single-use items that end up in landfills or the environment. Globally, less than 10% of plastic waste is recycled. Polymer upcycling could play an important role in addressing this growing challenge of global plastic waste accumulation.

Researchers at the Department of Energy’s Oak Ridge National Laboratory have developed an upcycling approach that adds value to discarded plastics for reuse in additive manufacturing or 3D printing. Their readily adoptable, scalable method introduces a closed-loop strategy that could globally reduce plastic waste and cut carbon emissions tied to plastic production.

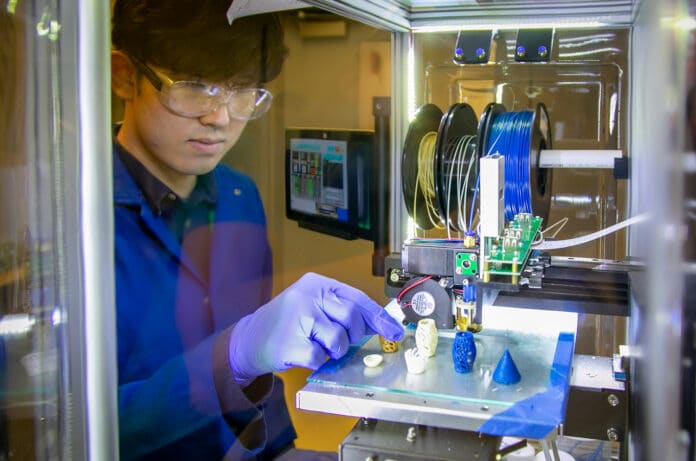

The team upgraded a prominent thermoplastic, acrylonitrile butadiene styrene (ABS), which is a popular feedstock for one of the most widely used 3D printing methods, called fused filament fabrication (FFF). The upcycled version boasts enhanced strength, toughness, and chemical resistance, making it attractive for FFF to meet new and higher-performance applications.

FFF printing requires materials that can be extruded or pushed through a heated nozzle to form the threads of 3D structures, built layer by layer, like coiling a rope. As a thermoplastic material that responds to heat, ABS works well for the process because it can flow easily and harden quickly into strong, rigid structures. However, there are inherent weaknesses in the way the threads stack up and bind together.

The ORNL team applied click chemistry to convert the chemical makeup of ABS into a vitrimer, a type of polymer that combines the processability and recyclability of thermoplastics with the superior mechanochemical properties of thermosets, such as epoxy, which are typically not compatible with FFF. The synthesis uses widely available medical compounds that are mixed in a single step under mild conditions, followed by curing with heat.

The resulting upcycled ABS achieved approximately double the toughness and strength of standard ABS, with enhanced solvent resistance. Researchers say solvent resistance has added value because it allows us to easily separate the modified ABS from mixed, unsorted plastic waste commonly encountered in recycling scenarios.

They demonstrated the excellent compressive strength of the material with intricate 3D-printed geometric structures modeled on beetle wings. The team dissolved mixed plastic waste in various solvents. In each experiment, upcycled ABS maintained its structure, while all other plastics, including ABS, completely dissolved.

Recovered upcycled ABS can be reused again and again for FFF with minimal loss of properties. This extremely versatile approach enables both recycling and upcycling of mixed ABS waste containing any combination of standard, upcycled, or blended ABS. All are compatible with FFF and do not need to be separated prior to reprinting, but separation can easily be performed to offer a selection of useful materials for broad manufacturing applications.

“Developing new, recyclable materials with superior properties for FFF creates opportunities to make a big impact on plastic production and expand additive manufacturing capabilities that have the potential to reduce our carbon footprint,” said ORNL’s Sungjin Kim.

“This effort demonstrates a closed-loop for manufacturing plastic items, potentially with higher value and performance, using only existing plastic waste in one of the most accessible areas of additive manufacturing,” said lead author Tomonori Saito of ORNL’s Chemical Sciences Division.