Produced via electrolysis using electricity from the sun and wind, green hydrogen holds significant promise to help meet global energy demand while contributing to climate action goals. Iridium is a scarce material that is presently essential to electrolyzers working with the commonly used Proton Exchange Membrane (PEM) technology.

Researchers at TNO have been the first to develop a method that will require 200 times less iridium while still producing electrolyzers that perform 25% – 46% better than the current generation of electrolyzers. For this technique, a patent application has been filed.

“The expected growth of green hydrogen from 300 megawatts in 2020 to tens of gigawatts in 2030 has a flipside,” explains TNO expert Lennart van der Burg. “It implies a proportionately growing demand for the scarce iridium for the electrolyzers that will need to be built. Earlier TNO research revealed that the scaling up of electrolysis could be hampered by the extremely limited availability of scarce resources, especially iridium and platinum. In ten years’ time, the demand for iridium will vastly exceed its availability. Moreover, we rely on a small group of countries for its delivery, with all the risks that imply.”

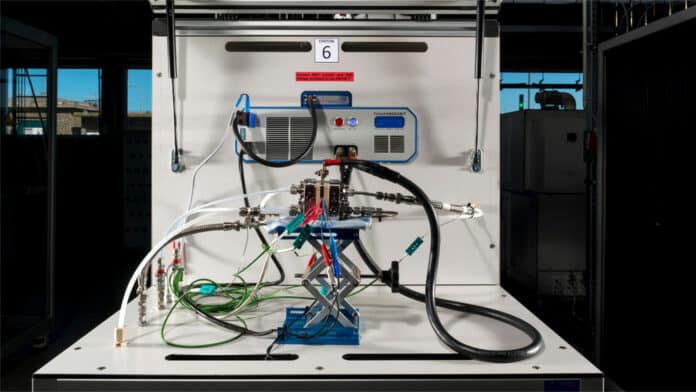

For this technological breakthrough, TNO researchers of the Faraday Lab in Petten, specializing in electrolysis, collaborated with colleagues from the Holst Centre in Eindhoven. TNO previously developed the spatial Atomic Layer Deposition (sALD) technology, a technique for depositing incredibly thin layers of functional materials to large surface areas. This technology was intended to birth the next generation of television, tablet, and smartphone displays. The research team has now also expanded the technology’s applicability to electrolyzers.

“The fact that we are reducing the required iridium by a factor of 200 while already achieving an average of one-third of the performance of current electrolyzers is a technological breakthrough,” says Van der Burg.

TNO researchers have spent the last two years experimenting with the sALD technology. They applied an ultrathin layer of iridium as a catalyst material on a porous transport layer of titanium instead of on a membrane. After different lab tests, the functionality and stability of the new method have been proven. There was little to no degradation after the initial stress testing. In addition to this, the electrolyzer’s membrane remains iridium-free, making it easier to recycle and reuse.

TNO is now working on moving this promising technology from the lab to practice. For this, the method needs to be scaled up to the pilot scale to demonstrate its functioning under real-life conditions.

“We’re not there yet,” warns van der Burg. “We’ve shown that the technology works in the lab, but we need to continue developing it to improve its lifespan, efficiency, and our capacity to produce it at scale.”

“Previously, TNO and several other European knowledge institutes already requested setting demands on the use of scarce materials when carrying out large pilot projects. It should be possible to apply the technology at a large scale in 2030. In this year, the European target of installed electrolysis capacity is set at 40 GW, which is by then hopefully using much smaller amounts of scarce materials.”