Ultra-small-sized cameras have great potential to detect problems in the human body and enable sensing for nanorobots, but past approaches captured fuzzy, distorted images with limited fields of view.

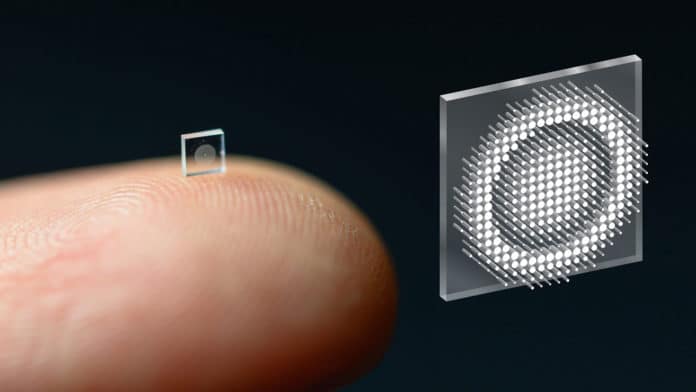

Now, a team of researchers from Princeton University and the University of Washington has developed an ultra-compact camera, the size of a coarse grain of salt, which can snap sharp, full-color images.

The new ultra-compact camera does not use a series of curved glass or plastic lenses to bend light rays into focus like traditional cameras. The new optical system relies on a technology called a metasurface, which can be produced much like a computer chip. Just half a millimeter wide, the metasurface is studded with 1.6 million cylindrical posts, each roughly the size of the human immunodeficiency virus (HIV). Each cylinder is carefully designed to bend light in just the right way so that the array as a whole correctly shapes the entire optical wavefront.

The researchers also developed signal processing algorithms to make it work and produce an image from that data. The camera can also work in natural light conditions, a novelty compared to other metasurface cameras created earlier. The post’s interactions with light combine to produce the highest-quality images and widest field of view for a full-color metasurface camera developed to date.

The team then compared the images produced with their system to the results of previous metasurface cameras and images captured by a conventional compound optic that uses a series of six refractive lenses. Aside from a bit of blurring at the edges of the frame, the nano-sized camera’s images were comparable to those of the traditional lens setup, which is more than 500,000 times larger in volume. Other ultracompact metasurface lenses have suffered from major image distortions, small fields of view, and limited ability to capture the full spectrum of visible light.

The metasurfaces are based on silicon nitride, a glass-like material that is compatible with standard semiconductor manufacturing methods used for computer chips. This means that a given metasurface design could be easily mass-produced at a lower cost than the lenses in conventional cameras.

Now the researchers are working on adding more computational abilities to the camera itself. Beyond optimizing image quality, they would like to add capabilities for object detection and other sensing modalities relevant for medicine and robotics.

Felix Heide, the study‘s senior author, also envisions using ultracompact imagers to create “surfaces as sensors.” “We could turn individual surfaces into cameras that have an ultra-high-resolution, so you wouldn’t need three cameras on the back of your phone anymore, but the whole back of your phone would become one giant camera. We can think of completely different ways to build devices in the future,” he said.