The railway system relies on compressed air for a variety of functions, including air brakes, door operations, suspension systems, radiator shutters, horns, and bells. It is estimated that the rail industry loses between 2-3% in vehicle efficiency every year, which occurs at various points throughout trains. These leaks can have a detrimental effect on train operability and safety.

To significantly reduce these leaks, Southwest Research Institute (SwRI) has developed a proof-of-concept system to autonomously detect compressed air leaks on trains and relay the location of the leaks to mechanical personnel for repair. The automated system could reduce the time, costs, and labor needed to find and repair air leaks, and it could lower the locomotive industry’s overall fuel consumption and exhaust emissions.

“Air leaks significantly increase fuel consumption and reduce the effectiveness of a locomotive’s automatic engine stop-start (AESS) systems, which causes locomotives to run more often, burn more fuel, and reduces the lifespan of parts such as starters, air compressors, and batteries,” said SwRI Lead Engineer Christopher Stoos. “We are talking potentially saving millions of gallons of fuel and reducing carbon dioxide, oxides of nitrogen, and particulate matter emissions.”

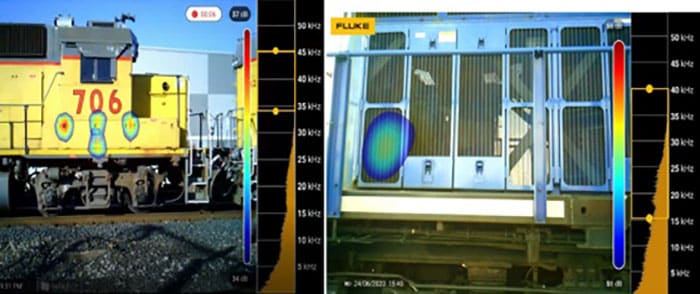

The system uses audio detection technology, cameras, and machine learning to autonomously detect, identify and report air leaks, even on moving trains. The system is equipped with Fluke SV600 fixed acoustic imager that uses a 64-microphone array and camera tuned to detect frequencies of 30-45kHz – the frequencies at which compressed air leaks best stand out from most background noise. This instrument works in concert with a secondary visual spectrum camera. In order to automate the detection process, the team trained and implemented machine learning algorithms to identify air leaks from the sensor outputs while ignoring non-leak-related outputs.

The prototype system was tested in the lab and successfully detected a range of air leaks at various locations on locomotives with a false positive rate of only 0.03%. The system detected, on average, 11 out of every 13 leaks on a moving train. Once an air leak was identified, an alert with an accompanying image was shared electronically with appropriate personnel showing the area in need of inspection and repairs.

“The system should reduce the burden on mechanical personnel and improve the compressed air system’s performance,” said Stoos.