‘Lego-like’ universal connector makes assembling stretchable devices a snap! A team of researchers from Nanyang Technological University, Singapore (NTU Singapore) has developed a universal connector to assemble stretchable devices simply and quickly in a ‘Lego-like’ manner.

Stretchable devices, including soft robots and wearable healthcare devices, are assembled using several different modules with different material characteristics – some soft, some rigid, and some encapsulated.

However, the commercial pastes (glue) currently used to connect the modules often either fail to transmit mechanical and electrical signals reliably when deformed or break easily. Making easily assembled stretchable devices without compromising their strength and reliability under stress has been a long-standing challenge limiting their development.

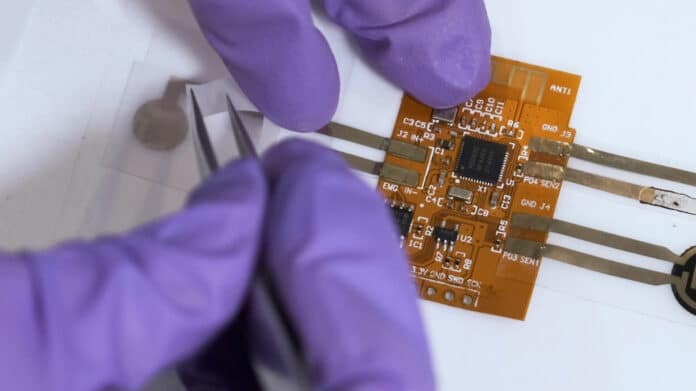

NTU team’s ribbon-like connector, called the BIND interface (biphasic, nano-dispersed interface), makes the assembly of stretchable devices simple while offering excellent mechanical and electrical performance. Just like building structures with Lego blocks, high-performing stretchable devices can be assembled by simply pressing together any module bearing the BIND interface.

It consists of a soft thermoplastic widely used in stretchable electronics (styrene-ethylene-butylene styrene). Embedded within the thermoplastic matrix are electrically conductive nanoparticles of gold or silver.

“Our breakthrough innovation makes it very easy to form and use a stretchable device since it works like a ‘universal connector,'” the Lead author of the study, Chen Xiaodong, said. “Any electronic module bearing the BIND interface can be connected simply by pressing them together for less than 10 seconds. Moreover, we do away with the cumbersome process of building customized interfaces for specific systems, which we believe will help accelerate the development of stretchable devices.”

The tests carried out have demonstrated excellent performance: the sensors built with the ‘Lego technique’ withstood the stretching of up to seven times their original length before breaking. Also, the electrical transmission of modules remained robust up to 2.8 times its original length when stretched.

The BIND interface was also evaluated for its interfacial toughness using a standard Peel Adhesion Test. For encapsulation modules, researchers found the innovation to be 60 times tougher than conventional connectors.

The team has filed an international patent for the innovation. For the next steps, the research team is developing a more efficient printing technology to expand the material choice and final application of this innovation to accelerate its translation from the lab to the design and manufacturing of products.

Journal reference:

- Ying Jiang, Shaobo Ji, Jing Sun, Jianping Huang, Yuanheng Li, Guijin Zou, Teddy Salim, Changxian Wang, Wenlong Li, Haoran Jin, Jie Xu, Sihong Wang, Ting Lei, Xuzhou Yan, Wendy Yen Xian Peh, Shih-Cheng Yen, Zhihua Liu, Mei Yu, Hang Zhao, Zechao Lu, Guanglin Li, Huajian Gao, Zhiyuan Liu, Zhenan Bao, and Xiaodong Chen. A universal interface for plug-and-play assembly of stretchable devices. Nature, 2023; DOI: 10.1038/s41586-022-05579-z