A race is on in solar engineering to create almost impossibly thin, flexible solar panels. Researchers at Stanford University have achieved record efficiencies in a promising group of new, ultrathin photovoltaic materials.

Made using transition metal dichalcogenides (TMDs), the materials absorb ultrahigh levels of the sunlight that strikes their surface compared to other solar materials. These materials provide an incredibly lightweight alternative to silicon-based solar panels.

The search for new materials is necessary because silicon – which makes up 95% of the solar market today – is much too heavy, bulky, and rigid for applications where flexibility, lightweight, and high power are preeminent, such as wearable devices and sensors or aerospace and electric vehicles.

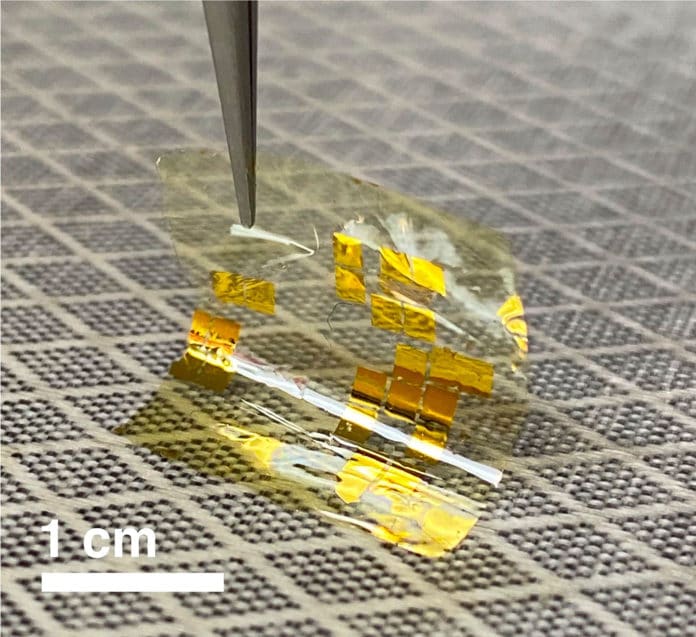

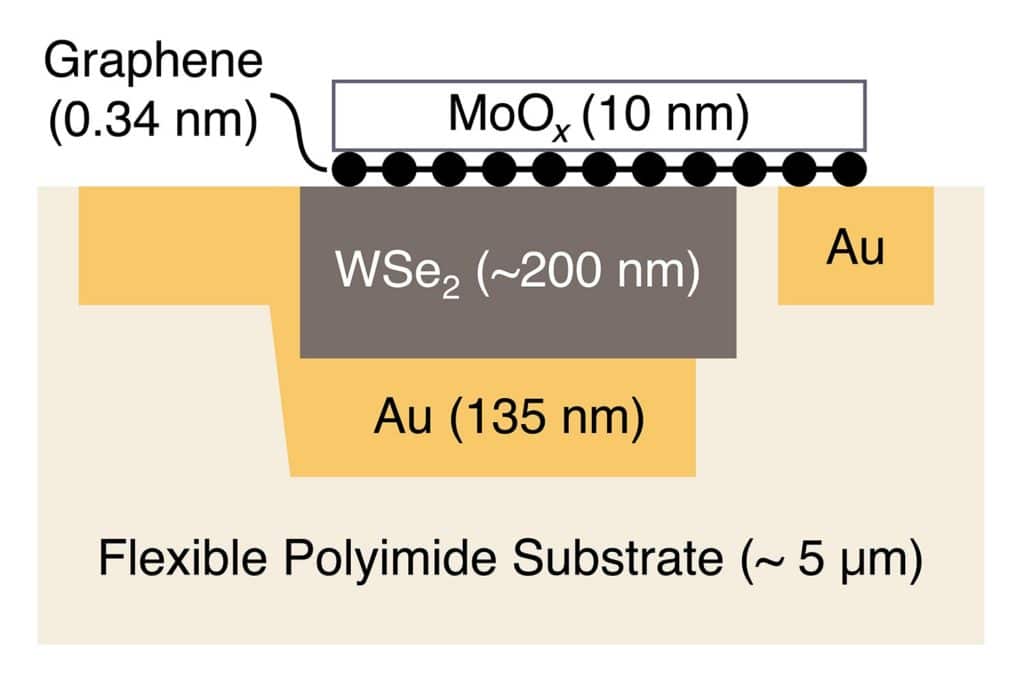

The Stanford team was able to produce an active array that is just a few hundred nanometers thick. The array includes the photovoltaic TMD tungsten diselenide and contacts of gold encased in a layer of conducting graphene that is just a single atom thick. All that is sandwiched between a flexible, skin-like polymer and an anti-reflective coating that improves the absorption of light. When fully assembled, the TMD cells themselves are less than six microns thick. It would take 15 layers to reach the thickness of a single piece of paper.

“Imagine an autonomous drone that powers itself with a solar array atop its wing that is 15 times thinner than a piece of paper,” said Koosha Nassiri Nazif, a doctoral scholar in electrical engineering at Stanford and co-lead author of a study. “That is the promise of TMDs.”

The new Stanford prototype achieves 5.1% power conversion efficiency, the highest reported for cells of this kind. However, the researchers project they could practically reach 27% efficiency upon optical and electrical optimizations.

In addition, the prototype realized a 100-times greater power-to-weight ratio of any TMDs yet developed. Its specific power, meanwhile, is 4.4 watts per gram, comparable with other current-day thin-film solar cells. Researchers estimated the practical limit of their TMD cells to be a remarkable 46 watts per gram.

Moreover, TMDs are stable and reliable over the long term and contain no toxic chemicals. They are also biocompatible, so they could be used in wearable applications requiring direct contact with human skin or tissue.

The researchers tested the flexibility and robustness of their devices by bending them around a metal cylinder less than a third of an inch thick. “Powerful, flexible, and durable, TMDs are a promising new direction in solar technology,” concluded Nassiri Nazif.