Researchers from Peter the Great St. Petersburg Polytechnic University (SPbPU), in collaboration with an industrial partner, are developing a new generation thermoelectric generator, which is ten times more efficient than its counterparts currently available on the market.

A thermoelectric generator is a device that converts thermal energy into electrical – a topic that has garnered much interest due to the global decarbonization trend. The new generator concept is based on a complex carbon nanostructure. During the heating process, the quantum electrodynamic processes occur, activating thermoelectric generation.

“We heat the structure which is created in a certain way and has a complex stoichiometry. Due to heating, the interaction of electronic subsystem and structural lattice is launched. As a result, the carbon nanostructure created by us begins to generate electrons. As a result of such a quantum-physical interaction under thermal exposure, the electric current appears,” said Olga Kvashenkina, Director of the Scientific and Technical Center, SPbPU.

The researchers completed theoretical studies devoted to the efficiency of the device, then created a digital model and conducted digital tests, considerably reducing the technology development time.

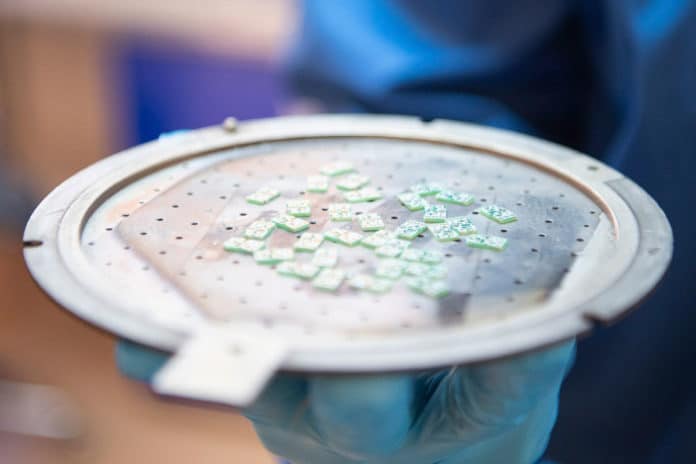

The simulation results were then verified during the experiments carried out using atomic force microscopes, various types of spectrometers, and a set of research equipment established specifically for this development. Currently, the project is at the hardware prototype stage. The device has a small size – measuring 5×2 mm and 1 mm in height – which makes it portable.

“The use of the thermoelectric generator is crucial not only for domestic use but also for the industry. For example, a device is placed on the surface of the turbine engine heated up to 1500 degrees, and this heat, turning into electrical energy, is transferred to sensors designed to monitor the state of this engine,” mentioned Olga Kvashenkina. “As for domestic use, now we are working to ensure that our development can charge the devices with low energy consumption such as electronic clocks, watering systems for indoor plants, and similar devices. In the future, we will strive to establish portable thermoelectric chargers for mobile phones.”

The heat from the central heating system will be enough to generate a sufficient current to charge household appliances. It is assumed that a thermoelectric generator should be installed near the heating system. The obtained electricity will be transferred to the electrical wiring and charge small devices. One of the key points is the safety of this system for both the user and the electronic equipment connected to this device.

Additionally, the system is designed for operation at very high temperatures due to its heat-resistant carbon nanostructure components ensures its suitability for industrial applications. Its refractory body can also be developed for industrial application if required. In the case of domestic use, the temperature of the room heating system will be sufficient for the device to generate electricity; no special requirements for materials of the device’s body will be needed. Therefore, the device can be made financially affordable for ordinary consumers.

The final product will be implemented by an industrial partner at the end of 2021. The project is conducted within the framework of the program World-class research center Advanced digital technologies of SPbPU.