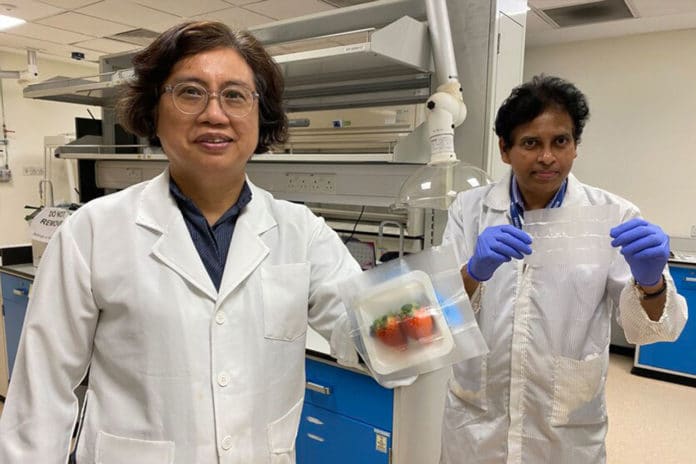

A team of researchers at Harvard University and Singapore’s Nanyang Technological University (NTU) has developed a smart food packaging material that is biodegradable, sustainable, and kills microbes that are harmful to humans. It could also extend the shelf-life of fresh fruit by two or three days. The material takes the form of a transparent film.

The packaging is made from a type of corn protein called zein, starch, and other naturally derived biopolymers, infused with a cocktail of natural antimicrobial compounds like thyme oil, citric acid, and acetic acid.

The food packaging is designed to release the necessary minuscule amounts of antimicrobial compounds only in response to the presence of additional humidity or bacteria, ensuring that it can withstand multiple exposures and last longer. In lab experiments, when exposed to an increase in humidity or enzymes from harmful bacteria, the fibers in the packaging have been shown to release the natural antimicrobial compounds, killing common dangerous bacteria that contaminate food, such as E. coli and Listeria, as well as fungi.

As the compounds combat any bacteria that grow on the surface of the packaging as well as on the food product itself, it has the potential to be used for a large variety of products, including ready-to-eat foods, raw meat, fruits, and vegetables.

In one of the research tests, the experts found that the strawberries wrapped in such packaging stayed fresh for seven days before developing mold, compared to four days for strawberries which were kept in regular fruit baskets.

According to researchers, the smart food package material, when scaled up, could serve as an alternative to cut down on the amount of plastic waste, as it is biodegradable. Its main ingredient, zein, is also produced from corn gluten meal, a waste by-product from using corn starch or oils to produce ethanol.

“The sustainable and biodegradable active food packaging, which has inbuilt technology to keep bacteria and fungus at bay, is of great importance to the food industry,” said Professor Mary Chan, who co-led the project. “It could serve as an environmentally friendly alternative to petroleum-based polymers used in commercial food packaging, such as plastic, which have a significant negative environmental impact.”

The team of NTU and Harvard Chan School researchers hope to scale up their technology with an industrial partner, with the aim of commercialization within the next few years. They are also currently working on developing other technologies to develop biopolymer-based smart food package materials to enhance food safety and quality.