So far, the production of green hydrogen has been considered energy-intensive for industry, regarding heat supply or transport. Because in several steps (including electrolysis), a lot of (heat) energy has to be used. However, the game is changing with technical progress and new cleantech systems.

“Greener than green” hydrogen

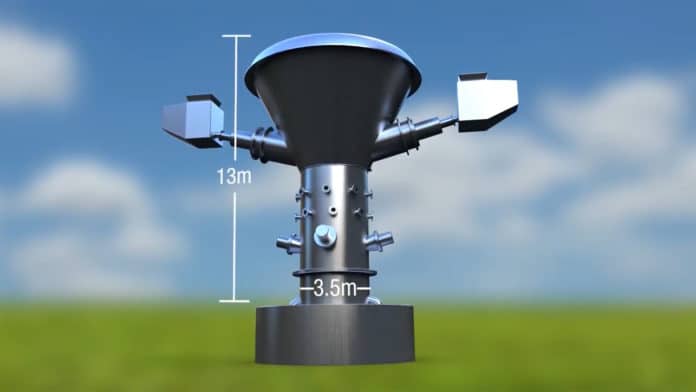

An interesting solution comes from the California company SGH2, which uses high-tech technology to produce hydrogen from municipal waste. In addition, it is cheap and environmentally friendly. The world’s largest environmentally friendly hydrogen production facility for SGH2 is to be built in Lancaster, California. The project has several characteristic elements, besides obviously the record size of the structure.

Currently, hydrogen production can rely on relatively clean technologies such as the electrolysis of water supplied by renewables to dirtier techniques such as coal gasification or fossil fuels such as natural gas. The second options are still the most popular worldwide, as they are also the cheapest. However, these processes release carbon dioxide, and to make the carrier really clean; it would be necessary to add carbon capture and sequestration plants – an operation that would increase costs.

What makes the SGH2 project interesting, at least on paper, is the ability to produce super-green hydrogen from waste that would otherwise sit in a landfill and rot, with a much lower amount of CO2 than fossil fuel systems but at equally competitive prices. Compared to electrolysis technologies, carbon emissions could be reduced by two to three times more.

How does it work?

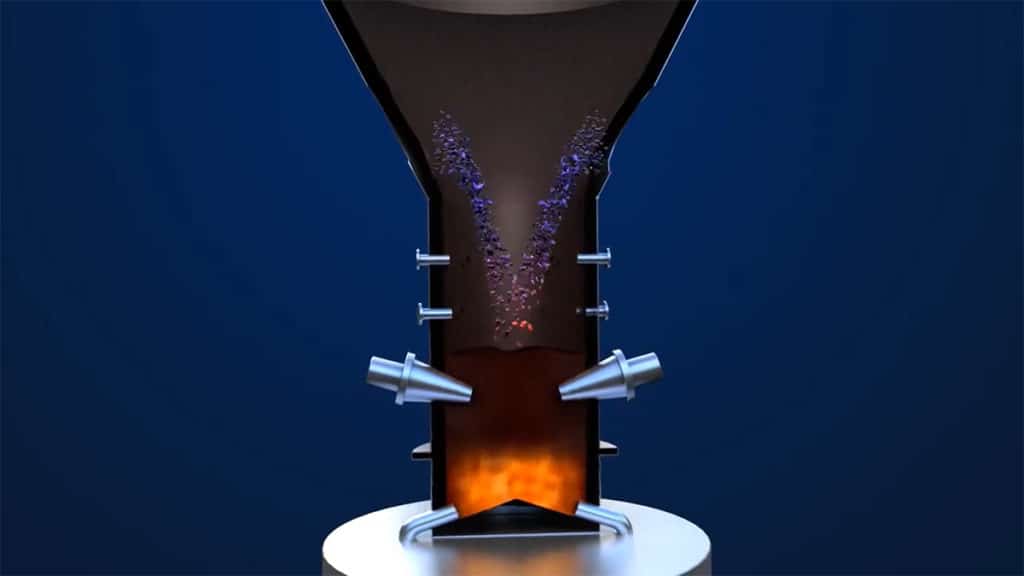

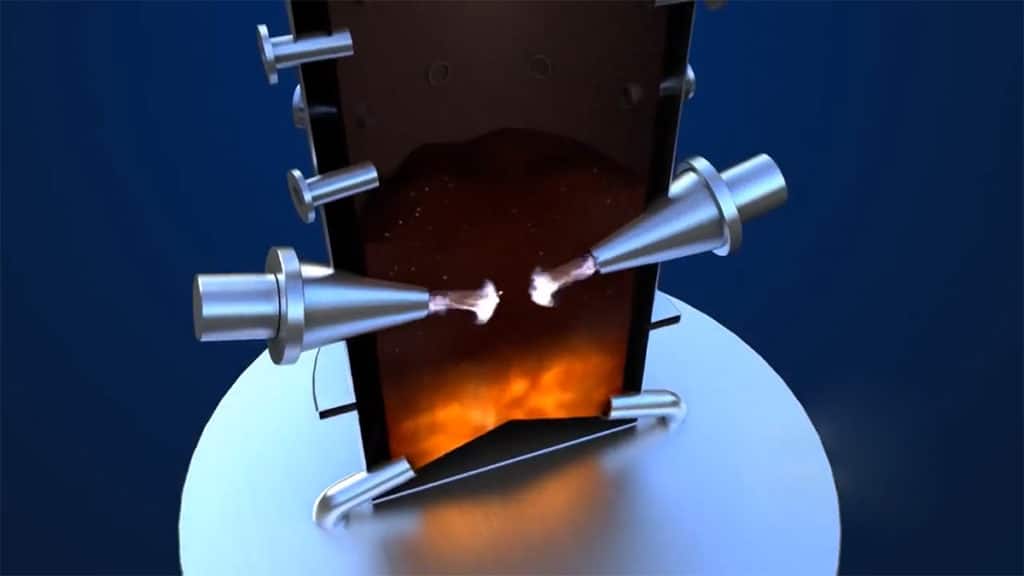

The process, developed by Solena (the parent company of SGH2), uses plasma torches that reach temperatures between 3,500 and 4,000 °C. This heat, with the addition of oxygen-enriched gas, catalyzes a complete molecular dissociation of all hydrocarbons of any fuel introduced into the system. And when it starts to cool, it forms a very high-quality hydrogen-rich biosynthesis gas that is free of tar, soot and heavy metals.

The syngas then passes through a pressure swing absorber system, which produces “greener than green” hydrogen, as is required for use in vehicles with PEM fuel cells. SGH2’s patented Solena Plasma Enhanced Gasification (SPEG) technology extracts all of the carbon from the waste, remove all particles and acid gases, and does not produce any toxins or contaminants. The end result is high-purity hydrogen and a small amount of biogenic carbon dioxide that does not contribute to greenhouse gas emissions.

The technology is capable of processing a wide range of waste, including paper, old tires, fabrics, and plastics, which it can handle without forming toxic by-products.

“The world needs some good news right now, and we have it. Affordable, mass-produced, reliable green hydrogen is the missing link needed to decarbonize the world,” said SGH2 CEO Dr. Robert T. Do. “We are the only company in the world delivering green hydrogen that is cost-competitive with the cheapest, dirtiest hydrogen made from coal and gas, and much less expensive than other green hydrogen. Our technology can scale quickly and produce fuel 24/7, year-round.”

More carbon reduction, less cost

The city of Lancaster will be a co-owner of the environmentally friendly hydrogen production facility, according to a recent memorandum of understanding. The SGH2 plant in Lancaster will be able to produce up to 11,000 kilograms of green hydrogen per day and 3.8 million kilograms per year – almost three times more than any other green hydrogen plant built or under construction worldwide. The plant will process 42,000 tons of recycled waste annually. Converting waste to clean fuel will result in an annual savings of $2.1 million to $3.2 million in landfill costs.

The Berkeley Lab conducted a preliminary life-cycle carbon analysis that found that SPEG technology reduced emissions by 23 to 31 tons of carbon dioxide equivalent for each ton of hydrogen produced, avoiding 13 to 19 tons more carbon dioxide per ton than any other green hydrogen process. And SGH2 hydrogen is said to be five to seven times cheaper than other green hydrogen, according to the cleantech company.

Furthermore, while electrolysis requires 62 KWh to produce 1 kg of hydrogen from 8 gallons of deionized water, the SGH2 process is energy positive. It generates its own power (1.8 Kwh per Kg of hydrogen) and does not require external power input to convert waste to hydrogen.

SGH2 expects the groundbreaking in the first quarter of 2021, commissioning in the fourth quarter of 2022 and full operation in the first quarter of 2023.