Self-healing soft electronic and robotic devices can, like human skin, recover autonomously from damage. Stanford University engineers have developed a multilayer, self-healing electronic skin that automatically realigns during healing.

This is a crucial step towards mimicking human skin, which has multiple layers that all re-assemble correctly during the healing process.

Layering is critical to mimicking skin’s many qualities. “It is soft and stretchable. But if you puncture it, slice it, or cut it – each layer will selectively heal with itself to restore the overall function,” says Sam Root, the co-author of a new study. “Just like real skin.”

To develop the new self-healing electronics skin, researchers used two dynamic polymers – PPG (polypropylene glycol) and PDMS (polydimethylsiloxane, better known as silicone). Both these polymers have rubber-like electrical and mechanical properties and biocompatibility and can be mixed with nano- or microparticles to enable electric conductivity.

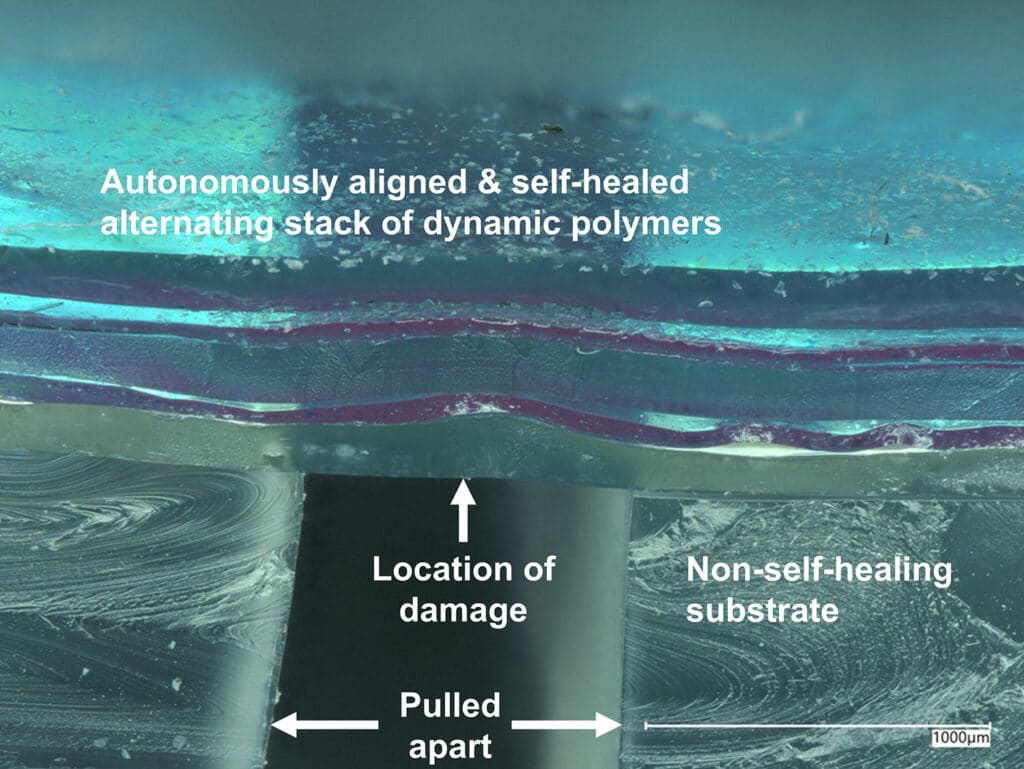

The chosen polymers and their respective composites are immiscible. They don’t mix with one another yet; due to the dynamic hydrogen bonding, they adhere to one another well to create a durable, multilayer material.

When warmed, both polymers soften and flow but solidify as they cool. Researchers were able to speed the healing process by warming the synthetic skin.

At room temperature, healing can take as long as a week, but when heated to just 70°C (158°F), the self-alignment and healing happen in about 24 hours. Researchers carefully designed the two materials to have similar viscous and elastic responses to external stress over an appropriate temperature range.

The team then added magnetic materials to their polymer layers, allowing the synthetic skin to not only heal but also to self-assemble from separate pieces. “Combining with magnetic field-guided navigation and induction heating,” says Professor Renee Zhao at Stanford University, “we may be able to build reconfigurable soft robots that can change shape and sense their deformation on demand.”

In the next step, researchers plan to make the layers as thin as possible and toward creating layers of varying function. While the current prototype is engineered to sense pressure, additional layers engineered to sense changes in temperature or strain could be included.

With their synthetic skin, researchers imagine robots that could be swallowed in pieces and then self-assemble inside the body to perform non-invasive medical treatments. Other applications include multi-sensory, self-healing electronic skins that form-fit to robots and provide them with a sense of touch.

“Our long-term vision is to create devices that can recover from extreme damage. For example, imagine a device that, when torn into pieces and ripped apart, could reconstruct itself autonomously,” Cooper says.

Journal reference:

- Christopher B. Cooper, Samuel E. Root, Lukas Michalek, Shuai Wu, Jian-Cheng Lai, Muhammad Khatib, Solomon T. Oyakhire, Renee Zhao, Jian Qin, Zhenan Bao. Autonomous alignment and healing in multilayer soft electronics using immiscible dynamic polymers. Science, 2023; DOI: 10.1126/science.adh0619