Researchers at Oxford University have developed a sensor made of sapphire fiber that can tolerate ultrahigh temperatures and high radiation. The novel sensor could be put to work in the harsh environment of nuclear fusion power generation and enable more streamlined air travel.

The breakthrough is billed as a solution to a 20-year-old problem with existing sensors. The research is based on Fiber Bragg grating (FBG) sensors that are widely used for remote monitoring strain and temperature in optical communication systems. These generally come in the form of silica optical fiber, but the operational temperature range of silica FBGs is constrained to less than 1000°C.

For their work, the researchers used sapphire optical fiber, which can withstand temperatures over 2000°C. It also promises great long-term stability at higher temperatures. This ultrahigh temperature operation, therefore, has potential for applications such as monitoring gas turbines in aero engines to enable significant improvements in efficiency and emission reduction. Sapphire is also radiation-hard, allowing measurements in nuclear reactors and avoiding radiation-darkening in space applications.

However, the Sapphire fiber Bragg grating has its own issues. The sapphire fiber seems very thin – less than half a millimeter thick – but in comparison to the wavelength of light, it is huge. This means that when light is injected onto one end of the sapphire fiber, it can take many different paths along the fiber, which results in many different wavelengths being reflected at once.

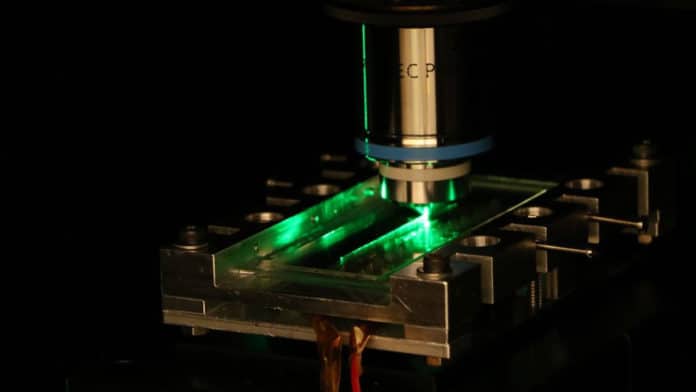

The researchers overcome this problem by writing a channel along the length of the fiber using a femtosecond laser. This way, the light is contained within a tiny cross-section, one-hundredth of a millimeter in diameter. With this approach, they were able to make a sensor reflecting predominantly a single wavelength of light.

In its initial demonstrations, the sapphire fiber was around 1 cm long, but researchers believe that lengths of up to several meters will be possible. This would enable temperature measurements to be made throughout a jet engine. Using this data to adapt engine conditions in-flight has the potential to significantly reduce nitrogen oxide emissions and improve overall efficiency, reducing the environmental impact.

“This is exciting news and yet another important scientific achievement resulting from our long-standing partnership with Oxford University. This fundamental research could, in time, enable more efficient and accurate multi-point temperature measurement in harsh environments, improving control, efficiency, and safety. We look forward to working with the University of Oxford to explore its potential,” said Mark Jefferies, Chief of University Research Liaison at Rolls-Royce, one of the partners on the project.

“These sapphire optical fibers will have many different potential applications within the extreme environments of a fusion energy powerplant,” said Rob Skilton, Head of Research at RACE, UK Atomic Energy Authority. “This technology has the potential to significantly increase the capabilities of the future sensor and robotic maintenance systems in this sector, helping UKAEA in its mission to deliver safe, sustainable, low carbon fusion power to the grid.”