For electric vehicles (EVs) to become mainstream, they need cost-effective, safer, longer-lasting batteries that won’t explode during use or harm the environment. Researchers at the Georgia Institute of Technology have found a promising alternative to conventional lithium-ion batteries made from a common material: rubber. The elastomers, or synthetic rubbers, with high conductivity, could make for safer electric vehicle batteries with a longer range.

In conventional lithium-ion batteries, ions are moved by a liquid electrolyte that ferries lithium ions between the electrodes. However, the battery is inherently unstable; even the slightest damage can leak into the electrolyte, leading to an explosion or fire. The safety issues have forced the industry to look at solid-state batteries, which can be made using inorganic ceramic material or organic polymers. But they can be somewhat fragile and do not have sufficient ionic conductivity and mechanical stability for the reliable operation of solid-state batteries.

The Georgia Tech researchers say their new elastomer electrolyte takes steps towards solving common problems – slow lithium-ion transport and poor mechanical properties. The material acts as a superhighway for fast lithium-ion transport with superior mechanical toughness, resulting in longer charging batteries that can go farther.

The key breakthrough was allowing the material to form a three-dimensional (3D) interconnected plastic crystal phase within the robust rubber matrix. This unique structure has resulted in high ionic conductivity, superior mechanical properties, and electrochemical stability.

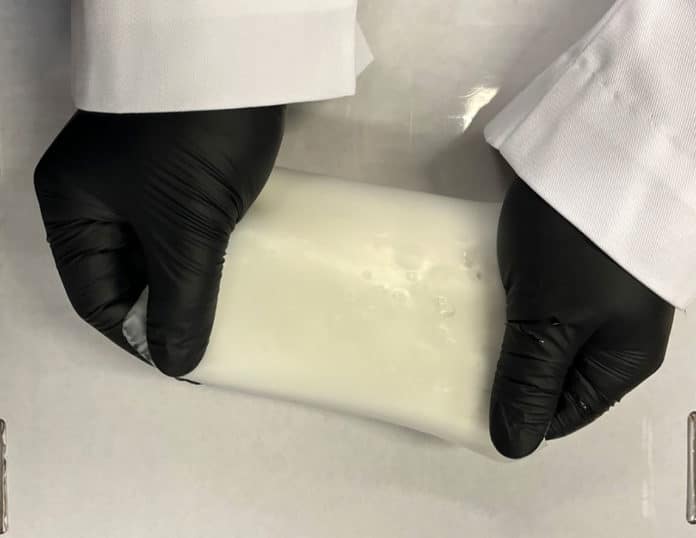

The rubber electrolyte can be made using a simple polymerization process at low-temperature conditions, generating robust and smooth interfaces on the surface of electrodes. This prevents lithium dendrite growth and allows for faster moving ions, enabling the reliable operation of solid-state batteries even at room temperature.

In lab tests, the lithium metal batteries made with the new rubber electrolyte were able to operate at a high voltage of 4.5 volts at ambient temperature, delivering high specific energy exceeding 410 watt-hours per kilogram of electrode plus electrolyte.

“Rubber has been used everywhere because of its high mechanical properties, and it will allow us to make cheap, more reliable, and safer batteries,” said Michael Lee, a mechanical engineering graduate researcher. “Higher ionic conductivity means you can move more ions at the same time. By increasing specific energy and energy density of these batteries, you can increase the mileage of the EV.”

The team is now investigating the ways to improve the battery performance by increasing its cycle time and decreasing the charging time through even better ionic conductivity. So far, their efforts have seen a two-time improvement in the battery’s performance/cycle time.