In our daily life, when we heat milk to boiling temperature, water evaporates, and protein accumulates to form skin on the surface of the cooked milk, known as milk skin.

Inspired by the milk-skin phenomenon, researchers from the University of Texas at Austin, Northeast Forestry University, and the Shenyang University of Chemical Technology have researched it in different materials to create multifunctional gel membranes that are easy to separate. Together they developed a “dip-and-peel” strategy for the simple and rapid fabrication of two-dimensional ionogel membranes.

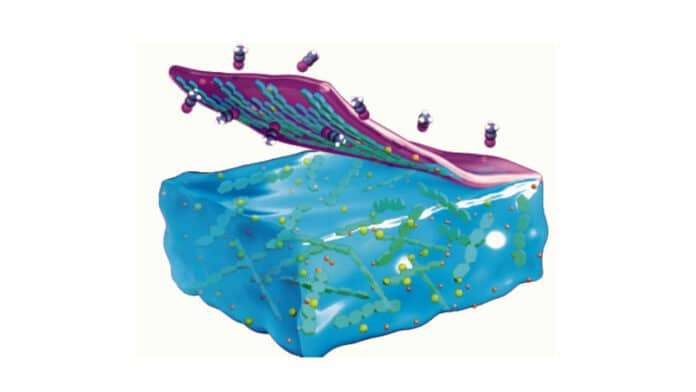

By dipping sustainable biomass materials in specific solvents, the molecules naturally respond by arranging themselves at the edges of the material into functional thin films that can be easily removed using nothing more than a simple set of tweezers.

These gel membranes are composed of a polymer network surrounded by an ionic liquid. They are similar in structure to hydrogels, where water is the liquid component. But, ionogels have a less rigid structure, allowing more room for ions to move around. Because of this, they are highly conductive and very sensitive.

“This simple yet effective solvent-induced self-assembly method really allows rapid and scalable production of 2D functional polymer films from different sustainable biomass materials, including cellulose, chitosan, silk fibroin, guar gum, and more,” said Nancy (Youhong) Guo, one of the lead authors on the paper.

The major innovation in the research is in the novel creation process, which works on different materials. The process can be reproduced hundreds or thousands of times at high speed and low cost. The films can be easily manipulated to be thicker, thinner, shaped, or coated with other materials.

These gel membranes have high potential as sensors, as part of wearable electronics that can more accurately track motion, heart rate, and other aspects of health monitoring. They can also serve as electrolytes in solid-state batteries. They are part of a safe battery that shuttles ions back and forth to facilitate charging and discharging.

The research team will work to further optimize the mechanical properties for more applications and advanced functionalities for next-generation technologies such as wearable electronics, smart robotics, and artificial intelligence.

Journal reference:

- Ying Zhu, Youhong Guo, Kaiyue Cao, Suqing Zeng, Geyuan Jiang, Yongzhuang Liu, Wanke Cheng, Wenjing Bai, Xuanli Weng, Wenshuai Chen, Dawei Zhao, Haipeng Yu & Guihua Yu. A general strategy for synthesizing bio-macromolecular ionogel membranes via solvent-induced self-assembly. Nature Synthesis, 2023; DOI: 10.1038/s44160-023-00315-5