The unprecedented growth of electric vehicles during the past decade has played an indispensable role in paving the way for a carbon-neutral future. Although sales of these electric vehicles are increasing, there are several issues on the ground.

Researchers at the University of Texas at Austin are tackling two of the biggest challenges facing electric vehicles: limited range and slow recharging. The team has developed a new type of electrode for lithium-ion batteries that could unleash greater power and faster charging. They created thicker electrodes – the positively and negatively charged parts of the battery that deliver power to a device – using magnets to create a unique alignment that sidesteps common problems associated with sizing up these critical components.

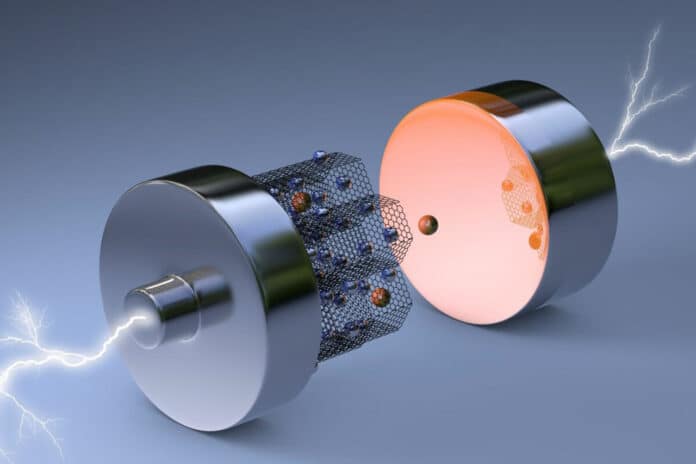

The resulting electrode could potentially facilitate twice the range on a single charge for an electric vehicle compared with a battery using an existing commercial electrode. The discovery uses thin two-dimensional materials as the building blocks of the electrode, stacking them to create thickness and then using a magnetic field to manipulate their orientations. The research team used commercially available magnets during the fabrication process to arrange the two-dimensional materials in a vertical alignment, creating a fast lane for ions to travel through the electrode.

This dense and thick electrode is capable of delivering a high volumetric capacity of over 1,600 mAh cm−3, with an areal capacity up to 32 mAh cm−2, which is among the best reported in the literature.

“Our electrode shows superior electrochemical performance partially due to the high mechanical strength, high electrical conductivity, and facilitated lithium-ion transport thanks to the unique architecture we designed,” said Zhengyu Ju, a graduate student in Yu’s research group who is leading this project.

The research team also fabricated a horizontally arranged electrode using the same materials for experimental control purposes. They were able to recharge the vertical thick electrode to 50% energy level in 30 minutes, compared with 2 hours and 30 minutes with the horizontal electrode.

The researchers emphasized they are early in their work in this area and looked at just a single type of battery electrode in this research. The goal is to generalize their methodology of vertically organized electrode layers to apply it to different types of electrodes using other materials. This could help the technique become more widely adopted in industry, so it could enable future fast-charging yet high-energy batteries that power electric vehicles.

Journal reference:

- Zhengyu Ju, Steven T. King, Xiao Xu, Xiao Zhang, Kasun U. Raigama, Kenneth J. Takeuchi, Amy C. Marschilok, Lei Wang, Esther S. Takeuchi, and Guihua Yu. Vertically assembled nanosheet networks for high-density thick battery electrodes. PNAS, 2022; DOI: 10.1073/pnas.2212777119