The fashion industry is one of the most polluting industries in the world. It produces 10% of all humanity’s carbon emissions, is the second-largest consumer of water and pollutes the oceans with microplastics. But now there is a way to put fashion first without putting the environment second.

The Swedish company Re:newcell has found a way to turn used cotton into a new biodegradable pulp called Circulose, which in turn can be made into new garments. The new material made from recycled cotton clothes was developed in response to the problem of waste generated in the fashion industry: instead of going to landfills or incinerators, cotton clothes are recycled and become material for new things.

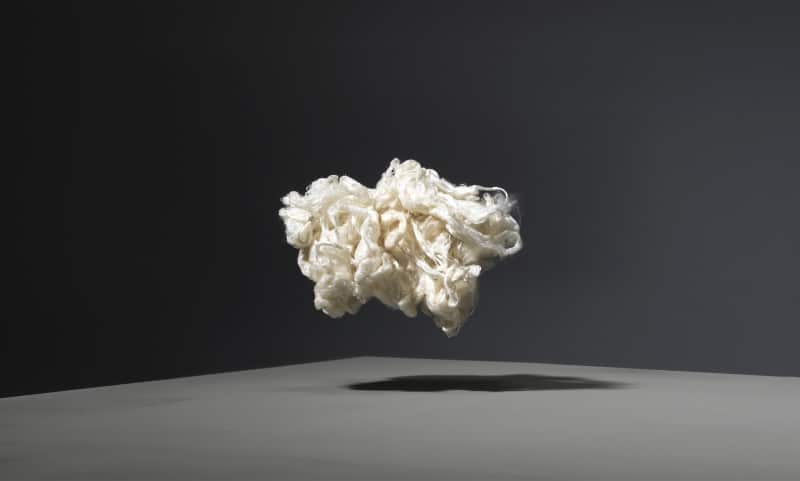

Circulose is made from fabrics with a high content of cellulose (cotton and viscose), whісh chemically dissolve to extract the fibers. The resulting slurry is dried to produce a biodegradable raw material called Circulose pulp, which returns to the textile production cycle. Used cotton fabrics are separated and “de-dyed” to remove color before being turned into a pulp.

This method is significantly more sustainable than traditional clothing production because it uses fewer chemicals and water and releases less carbon dioxide. Garments made using this process can be recycled several more times.

The Re:newcell plant produces about 7,000 tonnes of pulp each year. The material is certified, and its qualities are almost completely covered with those of known cotton fibers. They are organic, sustainable, and allow for better use of the planet’s resources.

As there are some 80 billion items of clothing produced each year globally, there is a huge potential for recycling. Re:newcell joins many other brands seeking to adopt circular design processes. Adidas, for instance, has produced a sneaker made from plastic that can be ground up and reused again.