UK-based aerospace company Orbex and FORCE Technology have been awarded a new contract from the European Space Agency (ESA) to further develop a high-energy X-Ray Inspection System for rocket engines.

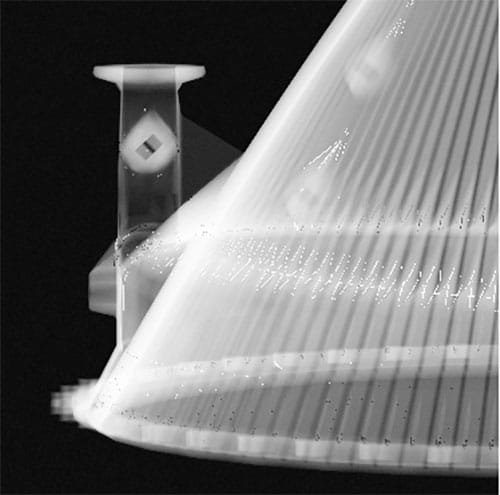

The innovative X-Ray Inspection System will enable the firms to carry out non-destructive, high-energy X-ray inspections of Orbex’s large-scale 3D-printed rocket engines prior to flight, using advanced technology to eliminate any internal flaws. It is expected to become a key component of the Orbex engine testing regime, reinforcing the reliability and safety credentials of the Orbex ‘Prime’ rocket.

Orbex will work closely with FORCE Technology to develop the system and will become one of the first launch operators to use this technology prior to the flight. The technology shows the detailed interior of rocket engines, just like a medical CT scanner, without damaging them in the process. It will help operators detect and eliminate potential internal flaws.

The next phase of the development will see the system extended to be used with very large structures, including Orbex’s fully 3D-printed rocket engine chambers.

Orbex has been manufacturing 3D-printed rocket engines since 2018. Its custom-made 3D printer is the largest high-precision metal 3D printer in use in Europe, enabling Orbex to produce the world’s largest monobody rocket engines.

Orbex is currently testing the Prime micro-launcher on the Orbex LP1 launch platform at a facility in Kinloss, close to the Orbex headquarters in Forres, where full dress rehearsals of launch procedures are taking place. It is designed to transport small satellites weighing around 150 kg to low Earth orbit. Orbex will commence launches from Space Hub Sutherland, the world’s first carbon-neutral spaceport in terms of construction and operation.

“Orbex is set to be the first launch operator to be able to carry out high-energy X-ray inspection of rocket engines prior to flight, using the unique technologies and IP we are helping to develop as part of our work with the ESA,” Orbex CEO Chris Larmour said. “As we move towards series production, we will use this new capability to give peace of mind to customers and assurance to licensing authorities that we have a fully comprehensive propulsion testing regime in place.”