A team of engineers from the National University of Singapore (NUS) has developed a reconfigurable hybrid robotic system that can grip a variety of objects: from the small, soft, and delicate to the large, heavy, and bulky. The robotic hand is touted to address the needs of sectors such as food assembly, vertical farming, and fast-moving consumer goods packaging, which will progressively automate more of their operations in the coming years.

To achieve human-like gripping abilities, robots need computer vision and deep learning to identify the type of objects in front of them and determine their orientation. The gripper can then automatically decide on how best to pick and place objects to minimize the necessity of intensive human intervention.

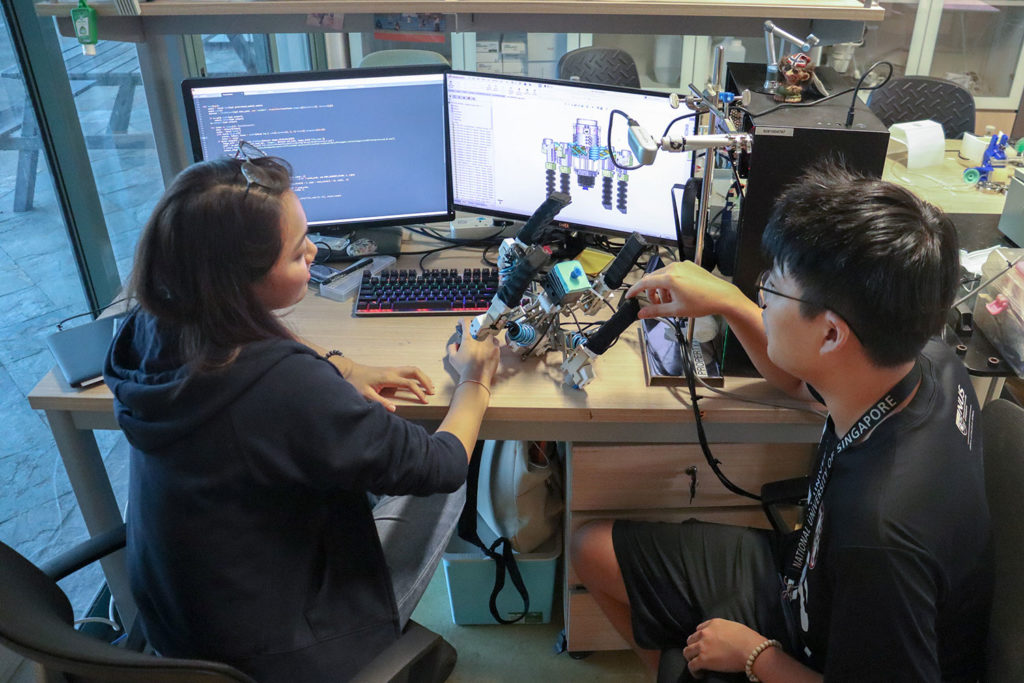

With the aim of developing robotic grippers that are as dexterous as human hands, the NUS team came up with hybrid robotic grippers, consisting of three or four soft, flexible 3D-printed fingers that sit on a reconfigurable gripper base. The fingers are air-driven and equipped with a novel locking mechanism that enables the level of stiffness to be adjusted.

“Our hybrid robotic gripper technology revolutionizes traditional pick-and-place tasks by offering advanced capabilities that allow robots to safely interact with delicate items of various shapes, sizes, and stiffness, just like the human hand,” Assoc Prof Yeow said.

The NUS team has developed three types of hybrid robotic gripper systems – almost like three different hands that are useful in different contexts. The first is GourmetGrip, which is suitable for the most granular tasks like handling delicate bite-sized food easily prone to damage like tofu and packs them into take-out boxes. This soft-handed mode is reconfigurable so that it can support different grip posses and operate within various space restrictions.

When mounted on an industrial robotic arm, GourmetGrip can achieve pick-and-place of food items at speed comparable to that of a human, and it can perform these tasks at a consistent pace round the clock. The GourmetGrip system is able to deliver about 23% improvement in gripping efficiency, with the ability to hold items faster and more precisely. GourmetGrip currently can effectively pick up more than 50 types of food items, including pudding, sliced cakes, and fruits.

Another gripper option is UnisoGrip, or Universal Soft Gripper, designed for handling packaged goods along the assembly line when they are usually at the final stage of being placed into boxes for shipping and transportation. It has soft rotatable gripper fingers for delicate grasping and a vacuum suction cup.

UnisoGrip is significantly larger and can handle items that are up to 30 centimeters wide and weigh up to three kilograms. It also has a 20% higher gripping efficiency than other commercially available grippers. To date, the UnisoGrip system can pick up over 30 different types of consumer goods such as bottled drinks, coffee powder packs, refillable detergent packs, and more.

The third type of gripper is one that is fully customizable, based on the GourmetGrip and UnisoGrip platforms, to adapt to specific client needs and space constraints. This approach offers a wide variety of gripping options that can handle objects of different shapes, sizes, and packaging materials.

The NUS engineers, through their startup company RO+, are now looking to commercialize the robotic fingers. RO+ also plans to offer a 4-in-1 solution which includes the gripper, robotic arm, computer vision module, and conveyor system.