Scientists at Nanyang Technological University, Singapore (NTU Singapore) have developed a long-lasting anti-fogging coating that, when applied to a plastic surface such as eyeglass lenses or photographic lenses, prevents fogging and is capable of self-cleaning. The coating is claimed to last for years without the need for frequent reapplications.

The transparent film is made of a thin double-layered silicon dioxide – titanium dioxide film is applied through a two-step technique. The plastic surface is first treated with oxygen plasma, an ionized gas, to improve adhesion and durability. The double-layered film is then deposited on the plastic surface using pulsed laser deposition, in which a laser beam is focused to vaporize material from the intended coating targets to achieve the desired level of thickness of the film.

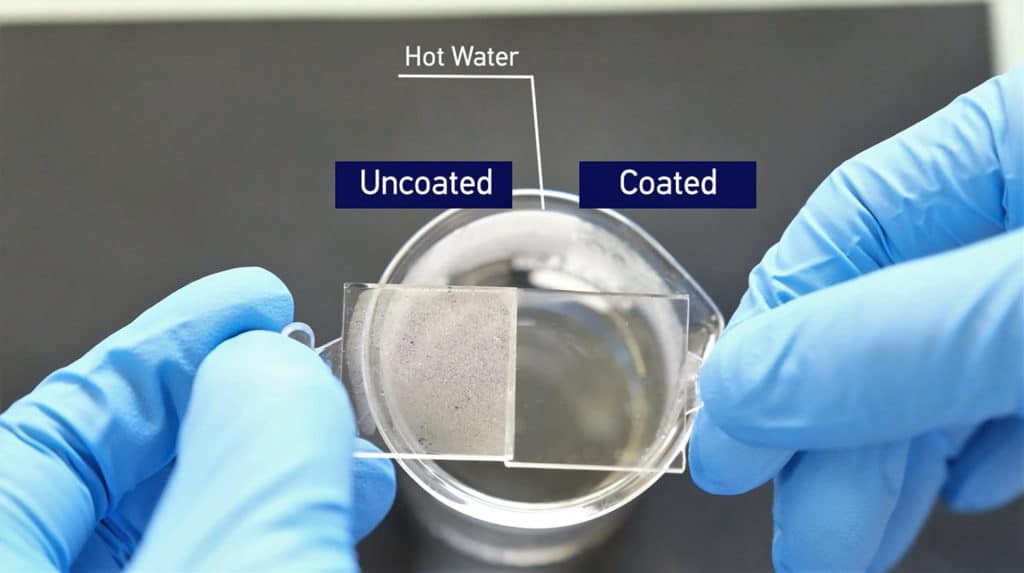

Fogging is observed when water vapor condenses as water droplets on a surface, which then scatter light and reduce visibility. So the anti-fogging coating is used to quickly spread these water droplets into a thin layer, allowing light to pass through the surface. Its performance is measured by the speed at which the condensed water droplets spread into a uniform film that does not block vision.

In the experiments, the new coating showed that it could spread the water droplets within 93 milliseconds, less than the duration of the average human eye blink of 100 milliseconds. The coating showed excellent adherence to the plastic surface. When subjected to abrasion using a cheese cloth pad – a standard test for optical coating, and an adhesion test using cellophane tapes, the coating maintained good durability.

In addition, the coating has the photocatalytic ability, meaning it can ‘self-clean’ by reacting with and removing organic residues under sunlight (ultraviolet light) exposure. In tests, it was also able to break down contaminants (i.e., bacteria, dirt) on the plastic surface after a full day of ultraviolet light exposure.

The newly developed coating has other beneficial properties, such as being antireflective. It also has a superior visible light transmittance of up to 89% on a regular plastic lens, about 5% better than the same lens without a coating. The NTU team expects the anti-fogging coating to have applications in a myriad of objects, ranging from spectacles, windshields to surveillance cameras and even solar panels.

“The reported results prove the multifunctionality of our coating,” said Sun Ye, a Ph.D. student at the School of MSE and first author of the study. “It is antireflective, anti-fogging, and self-cleaning. Additionally, the fabrication approach is fast and easy to implement with great durability. This makes our innovation unique among other anti-fogging methods which tend to end up with coatings with limited functions.”

The NTU research team has filed a Singapore patent for the innovation, and the team is looking to strike up industrial collaborations to take the innovation from lab to market.