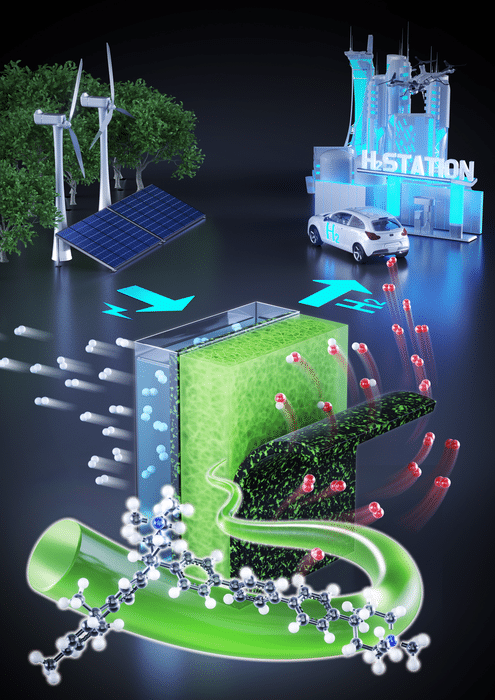

In recent times, hydrogen has received significant attention as a potential source of clean energy as an alternative to fossil fuels. In order to obtain hydrogen without harming the environment, active research is being carried out, and water electrolysis technologies are being developed that allow hydrogen to be extracted from water without emitting greenhouse gases.

Now, a research team from the Korea Institute of Science and Technology (KIST) has recently developed core technology for the next-generation water electrolysis system that has significantly improved the durability and performance while significantly lowering the cost of producing green hydrogen energy. Researchers have developed a membrane electrode assembly (MEA) for anion exchange membrane water electrolyzers (AEMWE) that are expected to replace the costly existing PEMWE technology.

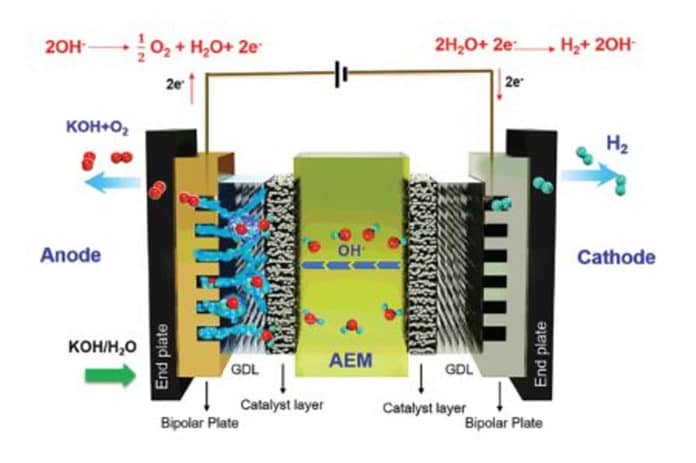

AEMWE, which uses an anion exchange membrane and electrode binder, does not rely on the expensive platinum group-metal electrodes and replaces the separator plate material of the water electrolysis cell with iron instead of titanium. When comparing the price of catalyst and separator material alone, the manufacturing cost is reduced by approximately 3,000 times that of the existing devices. However, it has not been commercially utilized owing to its low performance compared to that of the PEMWEs and durability issues of less than 100 hours of sustained operation.

The team developed poly(fluorenyl-co-aryl piperidinium) (PFAP)-based anion exchange materials with high ion conductivity and durability under alkaline conditions by increasing the specific surface area within the structure. And based on this technology, a membrane electrode assembly was developed. The developed material represented excellent durability of more than 1,000 hours of operation and has achieved a new record cell performance of 7.68 A/cm2. This is about six times the performance of existing anion exchange materials and about 1.2 times that of the expensive commercial PEMWE technology (6 A/cm2).

The new membrane and electrode assembly outperforms prior AEMs by a factor of six and outlasts them by a factor of at least 10. What’s more, it’s even got a 20% performance edge over current PEM technology. The technology has overcome the performance and durability issues of the core materials pointed out as limitations in the AEMWE technology to date.

In addition to the excellent performance and durability, the commercialization of the developed anion exchange membrane materials has been underway with the incorporation of large-capacity and large-area applications.

Professor Young Moo Lee of Hanyang University said, “The developed material has a high potential for application as a core material for not only water electrolysis but also for the hydrogen fuel cells, carbon capture utilization, and direct ammonia fuel cells, which are the next-generation hydrogen industry.”