The electrification of the automotive sector is causing a headache for all brands. Giving shape to the technologies that make it up is not easy and also much less economical. And so it happens that any model that uses this energy to move is sold at a prohibitive price. Hence, finding the balance point between costs and sale price is very necessary if the brands do not want to sink. And it seems like Nissan is close to achieving that.

As you know, Nissan was one of the first brands to mass-produce an electric vehicle. Nissan Leaf, the first mass-market electric vehicle in the world, hit the roads in December 2010. Although now other firms have surpassed it, their milestones will always be there. Its latest advance is a unique e-POWER electrified powertrain, utilizing its EV technology, which provides the same driving pleasure as an EV as it is 100% motor drive.

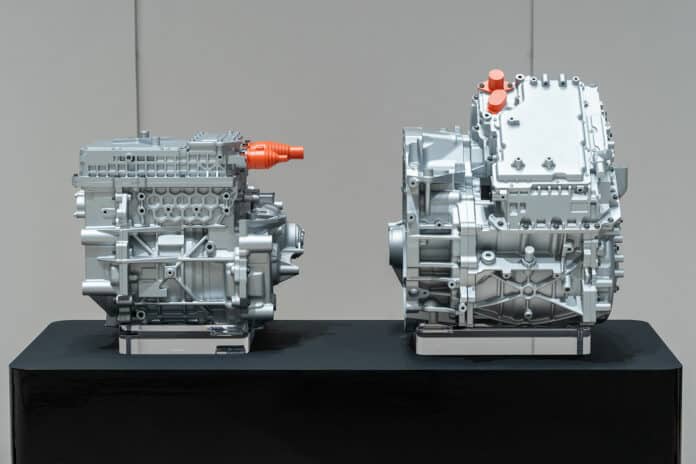

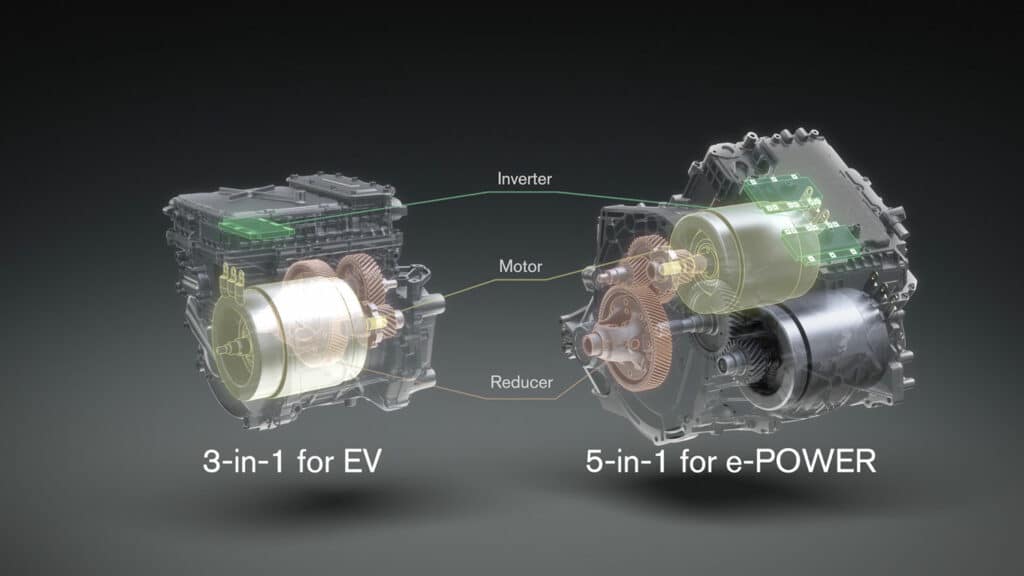

Now, the Japanese company has unveiled its new approach to electrified powertrain development, called “X-in-1,” which is expected to bring substantial cost savings. Under the approach, core EV and e-POWER powertrain components will be shared and modularized, resulting in a 30% reduction in development and manufacturing costs by 2026, compared to 2019 figures.

At the heart of this strategy is a dual approach, through which Nissan aims to further increase the competitiveness of its EV and e-POWER vehicles. Firstly, Nissan has developed a 3-in-1 powertrain prototype, which modularizes the motor, inverter, and reducer, which is planned for use in 100% electric cars. And a 5-in-1 prototype, which additionally modularizes the generator and increaser, is planned for use in e-POWER vehicles.

The X-in-1 approach, which covers 3-in-1, 5-in-1, and other possible variants, has been developed to enable EV and e-POWER core components to be produced on the same line.

The X-in-1 approach to electrified powertrain development provides the following benefits –

- Sharing and modularizing core components improve production efficiency and reduce powertrain costs by approximately 30% compared to 2019. Nissan aims to achieve e-POWER price parity with ICE vehicles around 2026

- Reducing unit size and weight improves driving performance and minimizes noise and vibration

- Adopt a newly developed motor that reduces the use of heavy rare earth elements to 1% or less of the magnet weight

- Sharing core components and control technology provides a pleasurable driving experience unique to Nissan EVs.

This is yet another of the measures taken by the Japanese brand under the Nissan Ambition 2030 program, according to which it will accelerate electrification in Europe with the launch of 27 new electrified models, including 19 EVs, by the fiscal year 2030.