Poor construction of roadways leads to potholes and road subsidence, which create serious hazards for drivers. This causes tire blowouts and structural damage to cars and trucks and also increases the chance of serious accidents.

Now, a research team from the University of Technology Sydney has developed a new “intelligent compaction” technology, which integrates into a road roller and can assess in real-time the quality of road base compaction. Improved road construction can reduce potholes and maintenance costs and lead to safer, more resilient roads.

The innovative machine-learning technique processes data from a sensor attached to a construction roller. “We have developed an advanced computer model that incorporates machine learning and big data from construction sites to predict the stiffness of compacted soil with a high degree of accuracy in a fraction of a second, so roller operators can make adjustments,” said Associate Professor Behzad Fatahi, who led the research, together with Professor Hadi Kahbbaz, Dr. Di Wu and Ph.D. student Zhengheng Xu.

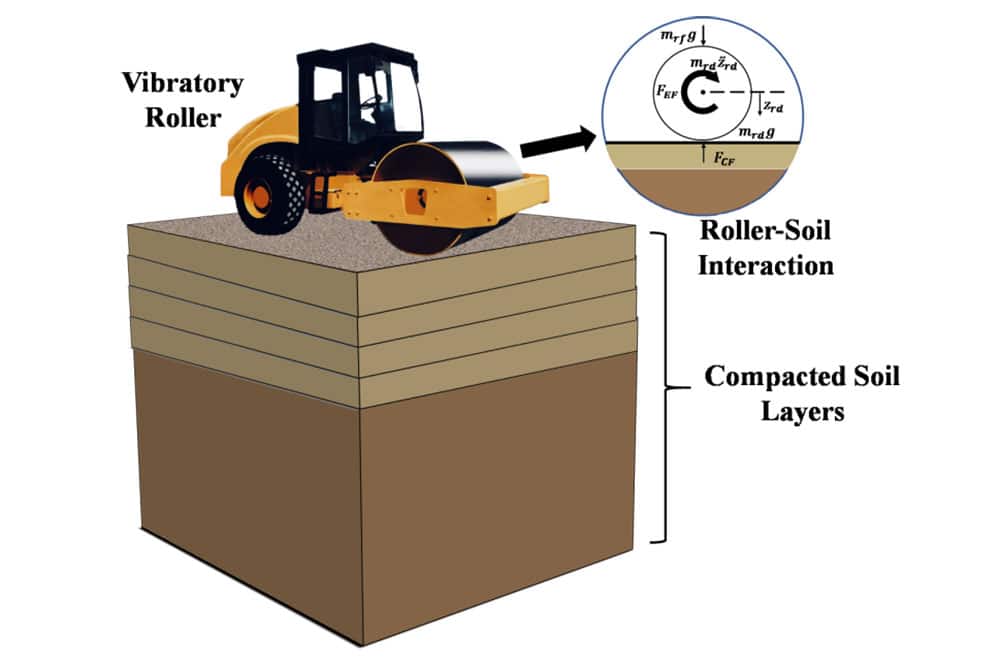

Roads are generally made up of three or more layers, which are rolled and compacted. The subgrade layer is usually soil, followed by natural materials such as crushed rock and then asphalt or concrete on top. The variable nature of soil and moisture conditions can result in under or over-compacted material.

The adopted machine learning method incorporating Gaussian Kernel and Generalised Gegenbauer Kernel functions can reasonably predict the double-layered soil modulus during roller compaction. Researchers conducted additional analyses to observe the proper training size and number of iterations to achieve real-time quality control to be used by site engineers.

“Like Goldilocks, the compaction needs to be ‘just right’ to provide the correct structural integrity and strength. Over-compaction can break down the material and change its composition, and under-compaction can lead to uneven settlement,” said Associate Professor Fatahi. “A well-compacted multi-layer road base provides a stable foundation and increases the capacity of a road to bear heavy loads. Trucks can weigh up to 40 tonnes, so a poor quality base can quickly lead to cracks and weak spots in the asphalt surface.”

The research suggests the application of this technology could help build longer-lasting roads that can better withstand severe weather conditions. Researchers are now looking to test the new technology onsite for various ground and roller conditions for road, railway and dam construction projects. Also, they plan to explore the techniques to measure the density and moisture content of the compacted soil in real time during construction.

Journal reference:

- Zhengheng Xu, Hadi Khabbaz, Behzad Fatahi and Di Wu. Double-layered granular soil modulus extraction for intelligent compaction using extended support vector machine learning considering soil-structure interaction. Engineering Structures, 2022; DOI: 10.1016/j.engstruct.2022.115180