Researchers at the Max Planck Institute for Polymer Research have focused on the life cycle of solid-state batteries and targeted processes that reduce it. More durable solid-state batteries could be realized in the future with their findings.

Many devices used on a daily basis, from e-cars and cell phones to cordless screwdrivers, now use rechargeable batteries. However, the trend also has its downsides. Lithium batteries are sensitive to high temperatures, and they are inherently capable of catching fire. Also, modern commercial lithium-ion batteries are sensitive to mechanical stress.

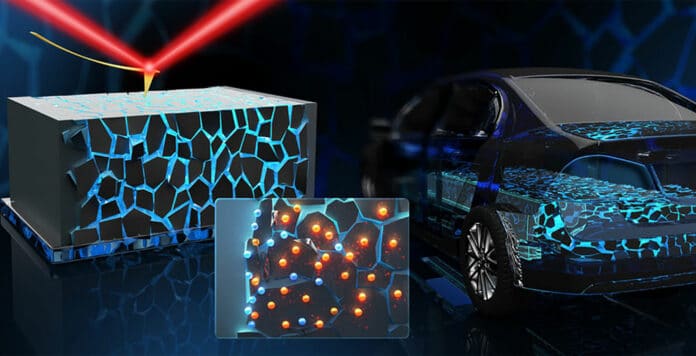

Solid-state batteries could offer a promising solution. The so-called solid-state batteries are considered the “Holy Grail” of battery research. They no longer have a liquid core like modern batteries but consist entirely of a solid material. As a result, they are mechanically robust, non-flammable, easy to miniaturize, and insensitive to temperature fluctuations.

Nevertheless, solid-state batteries begin to experience issues after several charging and discharging cycles. The positive and negative poles of the battery are still electrically separated from each other at the beginning, but they are eventually electrically connected to each other by internal battery processes.

Lithium dendrites slowly grow in the battery during each charging process until the two poles are connected. As a result, the battery is short-circuited and dies. However, further research is needed to understand the exact physical processes that take place in this process.

Researchers now use a special microscopy method to investigate the processes in more detail. They investigate how where the lithium dendrites start to grow. It is similar to a flowstone cave where stalactites grow from the ceiling and stalagmites from the floor until they join in the middle and form a so-called “stalagnate”? The battery has no top and bottom, but do dendrites grow from the negative to the positive pole or from the positive to the negative pole? Or do they grow equally from both poles? Or are there special places in the battery that lead to nucleation and then dendritic growth from there?

The team paid close attention to grain boundaries in the ceramic solid electrolyte that is formed during the production of the solid layer. The atoms in the crystals of the ceramic are basically very regularly arranged. However, due to small, random fluctuations in crystal growth, line-like structures are formed where the atoms are arranged irregularly, called grain boundaries.

These grain boundaries are visible with the Kelvin Probe Force Microscopy technique, in which the surface is scanned with a sharp tip. “If the solid-state battery is charged, the Kelvin Probe Force Microscopy sees that electrons accumulate along the grain boundaries – especially near the negative pole,” said Chao Zhu, a Ph.D. student working with Rüdiger Berger. The latter shows that the grain boundary changes not only the arrangement of the atoms of the ceramics but also their electronic structure.

Positively charged lithium ions traveling in the solid electrolyte can be reduced into metallic lithium due to the accumulation of electrons. As a result, lithium deposits and lithium dendrites form. The dendrite will continue to grow if the charging process is repeated until the poles of the battery are finally connected. The formation of such initial stages for dendrite growth was only observed at the negative pole, and no growth was observed at the opposite positive pole.

With a precise understanding of the growth processes, researchers hope to develop effective ways to prevent or at least limit growth at the negative pole so that, in the future, safer lithium solid-state batteries can also be used in broadband applications.

Journal reference:

- Chao Zhu, Till Fuchs, Stefan A. L. Weber, Felix. H. Richter, Gunnar Glasser, Franjo Weber, Hans-Jürgen Butt, Jürgen Janek and Rüdiger Berger. Understanding the evolution of lithium dendrites at Li6.25Al0.25La3Zr2O12 grain boundaries via operando microscopy techniques. Nature Communications, 2023; DOI: 10.1038/s41467-023-36792-7