Rare earth elements (REEs) are widely used in renewable energy technology and electronic devices, from cell phones, televisions, and computers to almost every part of a vehicle. The demand for these elements increases annually; however, their supply is geopolitically limited, and they are extracted by environmentally unsustainable mining practices.

Now, researchers from the McKelvey School of Engineering at Washington University in St. Louis have created a proof-of-concept solution – extracting REEs from coal fly ash, a fine, powdery waste product from the combustion of coal.

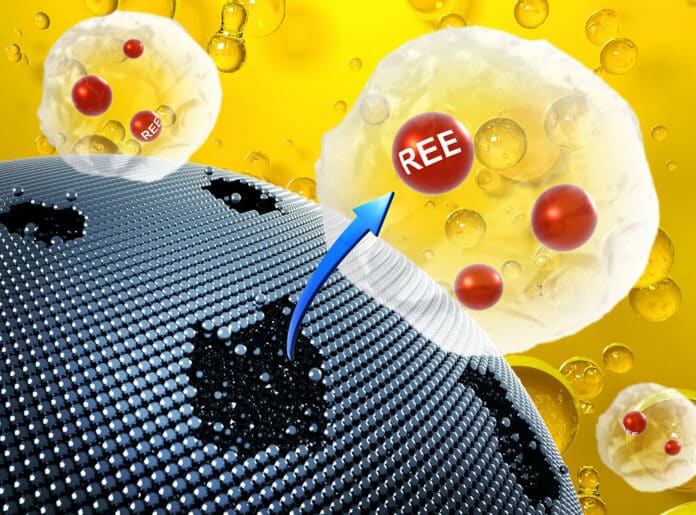

The team developed this novel extraction process using supercritical fluid, commonly used to decaffeinate coffee, to recover these critically needed REEs from material that would have otherwise been discarded in a landfill. A supercritical fluid is a substance at a temperature and pressure above its critical point with properties between a liquid and a gas.

“We wanted to use a greener process to extract REEs than traditionally more harmful processes,” said Young-Shin Jun, professor of energy, environmental & chemical engineering at the McKelvey School of Engineering. “Since the coal has already been used, this process is ultimately a pathway toward reduction and remediation of waste products.”

The new research showed that common and accessible supercritical fluids, including carbon dioxide, nitrogen, and air, were able to extract REEs and separate impurities very efficiently. Through experiments using coal fly ash, researchers also found that supercritical carbon dioxide decreased the concentrations of impurities in the final REE product. Ultimately, their final products contain up to 6.47% REEs, whereas the coal fly ash source initially contained only 0.0234% REEs.

The novel extraction process involved two steps. First, metal ions in the coal fly ash, including REEs and impurities, leach from the coal fly ash and react with nitric acid to form metal nitrates. And second, the metal nitrates react with tributyl phosphate (TBP). With supercritical carbon dioxide, nitrogen, or air, the rare earth elements formed complexes that could be extracted from coal fly ash.

After extraction, researchers’ multistage stripping process collected REEs and decreased the concentration of impurities. The nitric acid and TBP used in the process can be fully recycled multiple times without sacrificing efficiency, which minimizes their disposal concerns.

In addition, the new method eliminates the need to roast raw materials at extremely high temperatures, greater than 500 degrees Celsius. It also removes the need to extract the REEs with strong acids and a large quantity of toxic organic solvents, which also become a waste product in traditional extraction processes.

“Supercritical fluid is considered as a greener solvent, is less invasive to the environment, and allows us to extract REE directly from solid waste without leaching and roasting raw materials, so less energy is required for our new process, which also produces less waste,” Jun said. “We are seeking a more environmentally benign process for critical element recycling and recovery from materials previously considered to be waste.”

Journal reference:

- Yaguang Zhu, Guangcheng Wang, and Young-Shin Jun. Supercritical carbon dioxide/nitrogen/air extraction with multistage stripping enables selective recovery of rare earth elements from coal fly ashes. RSC Sustainability, 2023; DOI: 10.1039/D2SU00033D