Researchers around the world are seeking low-cost methods for producing clean hydrogen from water to replace fossil fuels as part of the quest to combat climate change.

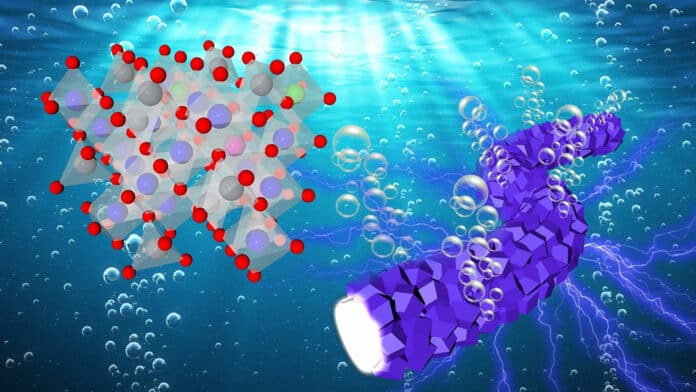

Water electrolysis is a potentially sustainable means of producing hydrogen, and the process has been around for more than a century. Unfortunately, only rare and expensive iridium is a sufficiently stable and active oxidation catalyst in the most efficient acidic environment. The lack of supply and high cost of iridium pose a major barrier to the widespread adoption of proton exchange membrane (PEM) electrolyzers.

Now, a team of researchers led by the U.S. Department of Energy’s (DOE) Argonne National Laboratory has developed a low-cost catalyst for a process that yields clean hydrogen from water.

Researchers say the main ingredient in their new catalyst is cobalt, which is substantially cheaper than iridium.

“We sought to develop a low-cost anode catalyst in a PEM electrolyzer that generates hydrogen at high throughput while consuming minimal energy,” said Di-Jia Liu, senior chemist at Argonne. “By using the cobalt-based catalyst prepared by our method, one could remove the main bottleneck of cost to producing clean hydrogen in an electrolyzer.”

Other contributors to the project include DOE’s Sandia National Laboratories and Lawrence Berkeley National Laboratory, as well as Giner Inc, a research and development company working toward the commercialization of electrolyzers and fuel cells.

The company evaluated the new catalyst using its PEM electrolyzer test stations under industrial operating conditions. Researchers say the performance and durability far exceeded that of competitors’ catalysts.

The research team deciphered critical structural changes that occur in the catalyst under operating conditions by using X-ray analyses at the Advanced Photon Source (APS) at Argonne. They also identified key catalyst features using electron microscopy at Sandia Labs and at Argonne’s Center for Nanoscale Materials (CNM). The APS and CNM are both DOE Office of Science user facilities.

“We imaged the atomic structure on the surface of the new catalyst at various stages of preparation,” said Jianguo Wen, an Argonne materials scientist.

Additionally, computational modeling at Berkeley Lab revealed important insights into the catalyst’s durability under reaction conditions.

“More generally, our results establish a promising path forward in replacing catalysts made from expensive precious metals with elements that are much less expensive and more abundant,” Liu noted.

Journal reference:

- Lina Chong, Guoping Gao, Jianguo Wen, Haixia Li, Haiping Xu, Zach Green, Joshua D. Sugar, A. Jeremy Kropf, Wenqian Xu, Xiao-Min Lin, Hui Xu, Lin-Wang Wang, Di-Jia Liu. La- and Mn-doped cobalt spinel oxygen evolution catalyst for proton exchange membrane electrolysis. Science, 2023; DOI: 10.1126/science.ade1499