VTOL aircraft are indispensable in places that cannot be reached by road and where there are no runways for airplanes. For example, for mountain rescue, for operations on oil platforms, for medical care in remote areas, or after accidents. But conventional helicopters consume more energy and achieve lower speeds in forward flight than fixed-wing aircraft.

The reason is that the rotor creates a lot of drag in flight. This is because the helicopter requires a rotor for vertical take-off and landing and to maintain a steady position in the air; however, the rotor has high aerodynamic drag when cruising.

Now, an international team of scientists from the Technical University of Munich (TUM) and Airbus Helicopters (AH) is working to develop an aircraft that can reach a speed of 248 mph (400 km/h) in forward flight and which is, in addition, quieter and greener than existing helicopters.

The Airbus demonstrator RACER (Rapid And Cost-Effective Rotorcraft) not only has a rotor but also features wings like an airplane. In this way, it can generate an aerodynamically efficient lift and reduce the load on the rotor.

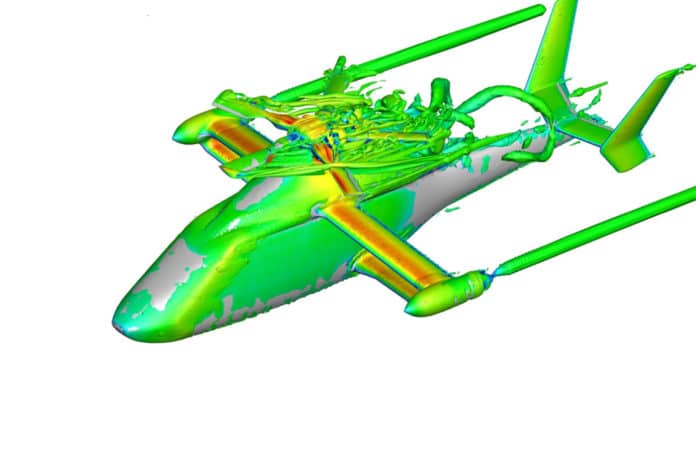

The aerodynamics of the rotorcraft play a significant role in achieving high cruising speed. In the FURADO (Full Fairing Rotor Head Aerodynamic Design Optimization) project, researchers have developed an aerodynamic fairing for the rotor head. “The fuselage and the rotor head are the components that cause the most drag when the helicopter is cruising,” says Patrick Pölzlbauer, a research assistant at TUM Chair of Aerodynamics and Fluid Mechanics.

The new aerodynamic rotor head full fairing will reduce energy consumption and make higher speeds possible.

Geometries have already been developed which reduce fuselage drag to the greatest extent possible. However, until now, there has been no aerodynamically optimized full fairing for the rotor head. The aerodynamics of the rotor is an extremely complex challenge, the team points out. This is why scientists combined this complex aerodynamic process with modern software and calculation methods.

Patrick Pölzlbauer successfully designed the shape of the rotor head in such a way that the flow stays attached as long as possible, and only minor turbulence arises. In addition, he has developed an “optimization chain for the aerodynamic design of geometries,” which in theory can also be used for the development of fairings for other rotor models.

It is planned to manufacture the developed rotor head fairing and test it on the flight demonstrator. The scientists are eagerly awaiting the RACER’s first flight tests, which will finally show whether or not the real aerodynamic improvements really produce the simulated results.