4D printing technology is known as the merge of 3D printing and intelligent materials. The integration of magneto-responsive shape memory polymers (SMPs) into 4D printing provides novel opportunities to create innovative and intelligent products controlled in a contactless method.

Now, researchers at Universidad Carlos III de Madrid (UC3M) have created software and hardware for a 4D printer with applications in the biomedical industry. This machine allows for controlling extra functions, such as programming the material’s response so that shape-changing occurs under an external magnetic field or changes in its electric properties develop under mechanical deformation.

This opens the door to the design of soft robots or smart sensors and substrates that transmit signals to different cellular systems, among other applications.

A new smart printer enables the manufacture of soft multifunctional structures, which consist of materials with mechanical properties that mimic biological tissues such as the brain or skin. In addition, they can change their shape or properties when actuated via external stimuli, such as magnetic fields or electric currents.

The team of researchers had made several advances in the design and manufacturing of these structures, but they were very limited in terms of shape design and programming of intelligent responses. The new work allows them to open up new possibilities by developing a novel4D printing methodology.

This sort of printing is complex since the material to be extruded transitions from liquid to solid during the printing process. So, it is necessary to understand the material dynamics to adapt the manufacturing process and obtain a material that is enough liquid to pass through the printer nozzle yet solid enough to hold a particular shape.

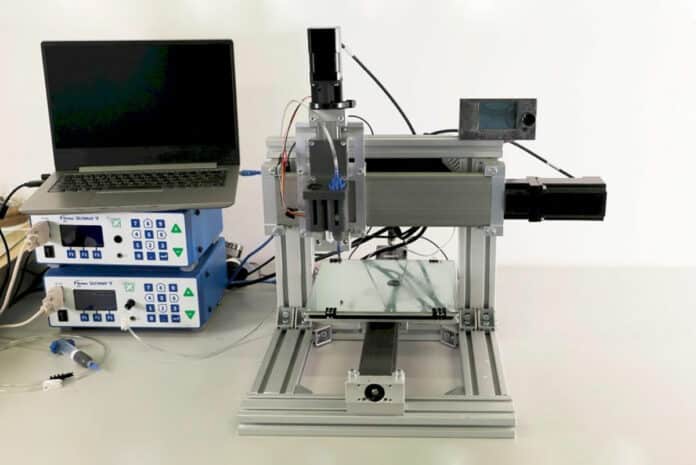

To achieve this, the team has developed an interdisciplinary methodology that combines theoretical and experimental techniques allowing them to build the printing device from scratch, both the hardware and the computer programs that allow it to be controlled.

The researchers have also created a new material concept that has the ability to heal itself autonomously without the need for external action.

“This material consists of a soft polymer matrix embedded with magnetic particles with a remanent field. For practical purposes, it is as if we had small magnets distributed in the material, so that, if it breaks, when the resulting parts are brought together again, they will physically join, recovering their structural integrity”, says Daniel García González, head of the ERC 4D-BIOMAP project.

The combination of materials with self-healing capabilities and whose electric conduction properties vary with deformation opens up enormous possibilities in the development of sensors.

Journal reference:

- Han Liu, Feifan Wang, Wenyang Wu, Xufeng Dong, Lin Sang. 4D printing of mechanically robust PLA/TPU/Fe3O4 magneto-responsive shape memory polymers for smart structures. Composites Part B: Engineering, 2023; DOI: 10.1016/j.compositesb.2022.110382