Japanese technology firm Mitsubishi Electric Corporation has developed an on-orbit additive-manufacturing technology that uses photosensitive resin and solar ultraviolet light for the 3D printing of satellite antennas in the vacuum of outer space.

The novel technology makes use of a newly developed liquid resin that was custom formulated for stability in a vacuum. The resin enables structures to be fabricated in space using a low-power process that utilizes the sun’s ultraviolet rays for photopolymerization.

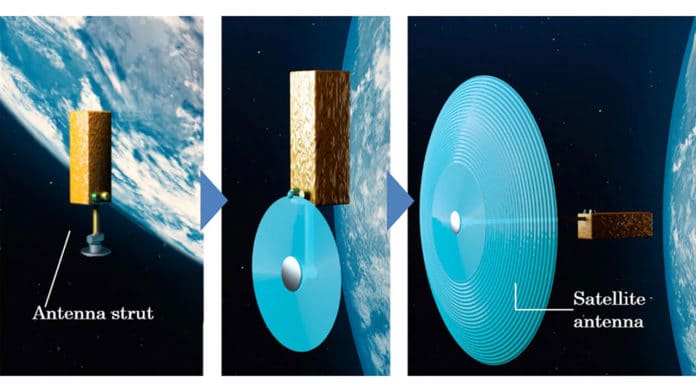

Using the new 3D printing technology, Mitsubishi hopes that in the future, it will be possible to print satellite antennas after the satellites have been launched into space. The on-orbit manufacturing and deployment of a satellite antenna in space could significantly reduce the weight and costs of satellite launches by removing the need to transport cumbersome parts that take up a lot of rocket space into orbit.

Mitsubishi has so far only tested new 3D printing technology in simulated space conditions in a test chamber. Researchers printed an antenna dish 6.5 inches wide that performed just as well as a conventional satellite antenna in tests. Whether there are plans to test the 3D printer in space and when this could happen, there is so far no information on that.

The resin-based on-orbit manufacturing is expected to enable spacecraft structures to be made thinner and lighter than conventional designs, which must survive the stresses of launch and orbit insertion. The technology specifically addresses the challenge of equipping small, inexpensive spacecraft buses with large structures, such as high-gain antenna reflectors, and enables on-orbit fabrication of structures that greatly exceed the dimensions of launch vehicle fairings.

Mitsubishi Electric’s resin-based on-orbit manufacturing enables small satellites to achieve large-satellite capabilities, which reduces launch costs and allows for satellite technology to be used more than ever in applications such as communication and Earth observation.

The photosensitive resin is also heat resistant and can survive in temperatures of at least 400°C, which is beyond the maximum temperature experienced in orbit.

“Spacecraft antenna designs are challenging due to their conflicting requirements for high gain, wide bandwidth, and low weight,” the company said in the statement. “High gain and wide bandwidth necessarily require a large aperture, but economical orbital deployment conventionally dictates that designs be lightweight and small enough to fit or fold inside a launch vehicle or satellite deployment mechanism.”

Mitsubishi also claims that by developing a 3D printer that extrudes a custom ultraviolet-curable resin formulated for vacuum, resin-based low-power “freeform additive-manufacturing in space has now become possible.”