Employing renewable materials for fabricating clean energy harvesting devices can further improve sustainability. Microorganisms can be mass produced with renewable feedstocks.

Researchers at the University of Massachusetts Amherst have demonstrated a microbial biofilm as a cohesive, flexible material that harvests the energy in evaporation and converts it to electricity. This biofilm has the potential to revolutionize the world of wearable electronics, powering everything from personal medical sensors to personal electronics.

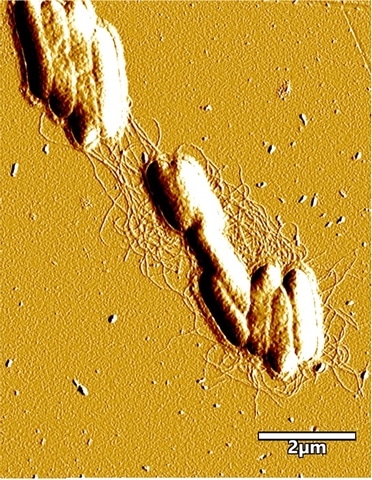

The biofilm is a thin sheet of bacterial cells about the thickness of a sheet of paper. It is produced naturally by an engineered version of the bacteria Geobacter sulfurreducens. This microbe is known to produce electricity and has been used previously in “microbial batteries” to power electrical devices. But such batteries require that G. sulfurreducens is properly cared for and fed a constant diet.

By contrast, the new biofilm, which can supply as much energy as a comparably sized battery, works continuously because it is dead. And because it’s dead, it doesn’t need to be fed.

“It’s much more efficient,” says Derek Lovley, Distinguished Professor of Microbiology at UMass Amherst and one of the paper’s senior authors. “We’ve simplified the process of generating electricity by radically cutting back on the amount of processing needed. We sustainably grow the cells in a biofilm and then use that agglomeration of cells. This cuts the energy inputs, makes everything simpler, and widens the potential applications.”

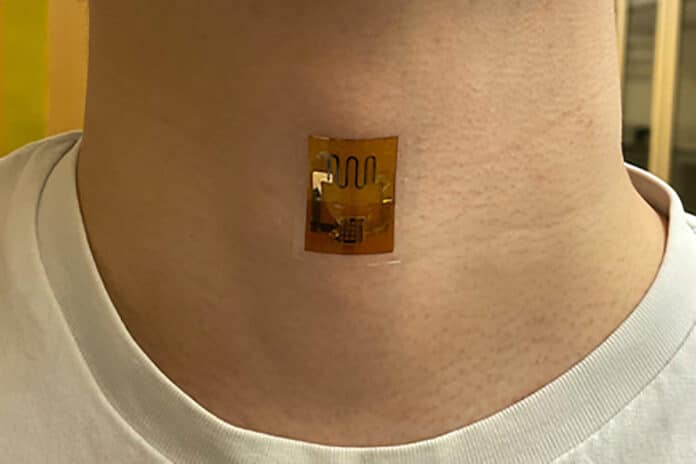

The G. sulfurreducens grows in colonies that look like thin mats, and each of the individual microbes connects to its neighbors through a series of what the research team calls “natural nanowires.” The team then harvests these mats and etches small circuits into them using a laser. Then, they’re sandwiched between electrodes and finally sealed in a soft, sticky, breathable polymer that you can apply directly to your skin. Since the surface of our skin is constantly moist with sweat, the biofilm can “plugin” and convert the energy locked in evaporation into enough energy to power small devices.

Researchers say the limiting factor of wearable electronics has always been the power supply. Batteries run down and have to be changed or charged. They are also bulky, heavy, and uncomfortable. But a clear, small, thin, flexible biofilm that produces a continuous and steady supply of electricity and which can be worn, like a Band-Aid, as a patch applied directly to the skin, solves all these problems.

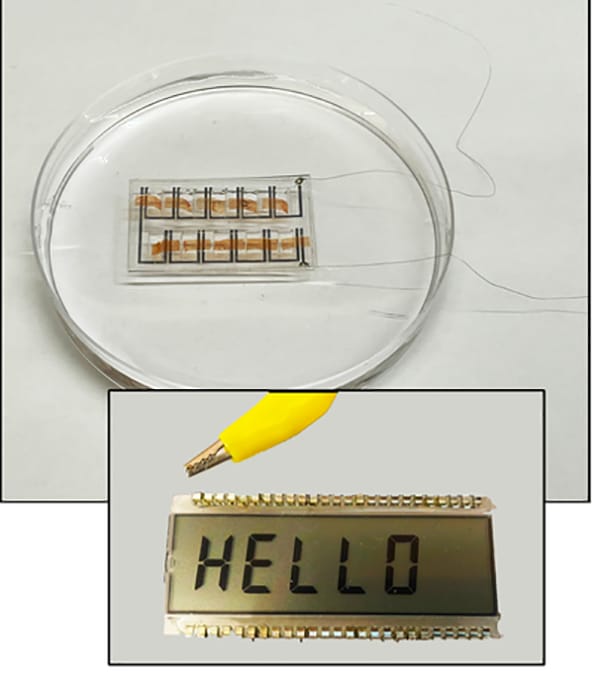

During experiments, the biofilm skin patch worn on sweaty skin produced power comparable to that produced with the salt solution and maintained its performance after 18 hours. Even non-sweating skin generated a substantial electric output, demonstrating that a continuous low-level secretion of moisture from the skin is sufficient to drive this hydroelectric output. In lab tests, the device maintained a steady current output for over 30 days. It could be a promising candidate for the continuous powering of wearable electronics.

“Our next step is to increase the size of our films to power more sophisticated skin-wearable electronics,” says Yao, and Liu points out that one of the goals is to power entire electronic systems rather than single devices.