A German automotive supplier, MAHLE, has announced a groundbreaking superior continuous torque (SCT) electric motor for electric vehicles that is considerably more durable than any other design currently in use. The traction motor can run indefinitely with high performance. It will be presented for the first time at IAA Transportation in September 2022 in Hanover.

The new electric motor is surpassingly clean, light, and efficient and can also be assembled without the use of rare earths by customer request. The new development is suitable for passenger cars and commercial vehicles as well as construction machines and tractors. With the SCT E-motor, MAHLE thus becomes a full-range provider in the field of electric drives and covers all needs from e-scooters to heavy-duty commercial vehicles as well as off-road and industrial applications.

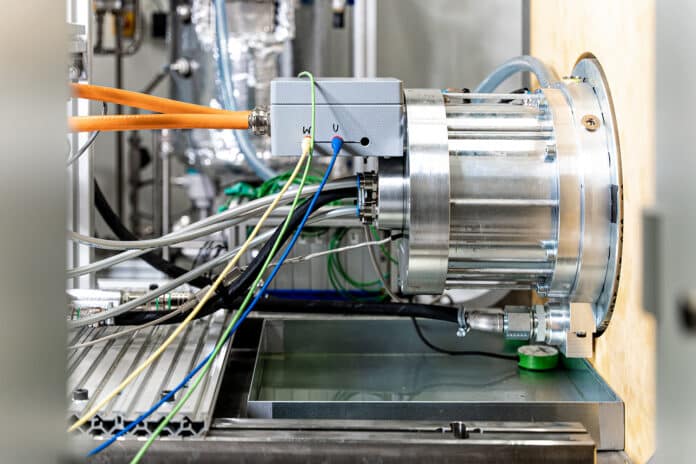

The SCT E-motor is designed in such a way that it is particularly efficient within a certain rpm range. Despite its very compact and light design, the electric motor is capable of continuously pounding out more than 90% of its peak power without overheating. This groundbreaking high ratio means a technological leap and allows the use of electric vehicles of all kinds, even under demanding conditions.

“Building large electric motors that deliver short-term high performance is easy. What was still lacking on the market until now were durable yet compact drives to make electric vehicles unrestricted for everyday use,” said Martin Berger, Vice President of Corporate Research and Advanced Engineering at MAHLE. “Our new SCT E-motor is the solution.”

The secret behind such an increase in durability of the new MAHLE electric motor is an innovative integrated oil cooling, which not only makes it more robust but also allows the waste heat generated to be used in the vehicle’s complete system.

MAHLE’s continuous torque motor, designed to run with neodymium magnets – currently the strongest permanent magnets that can be produced, has an extremely compact design. This results in an advantage in the costs of materials, dimensions, and weight – a lighter motor, in fact, requires less material during production and, if used on commercial vehicles, also increases the possible net load of the vehicle.

There’s more. At a time when the supply of rare earths is increasingly complex and expensive, the SCT electric motor can also be designed without magnets for greater independence. Thanks to the unique contactless transformer developed by MAHLE, the magnet-free variant would also be wear-free and run efficiently while only requiring slightly more assembly space.