Rice University engineers and researchers have developed a method for petrochemical refineries to turn a smelly byproduct into cash.

Hydrogen sulfide gas has the unmistakable aroma of rotten eggs. Thousands of tons of noxious gas are produced annually as a byproduct of processes that remove sulfur from petroleum, natural gas, coal, and other products. It frequently emanates from sewers, stockyards, and landfills, but it is particularly problematic for refineries, petrochemical plants, and other industries.

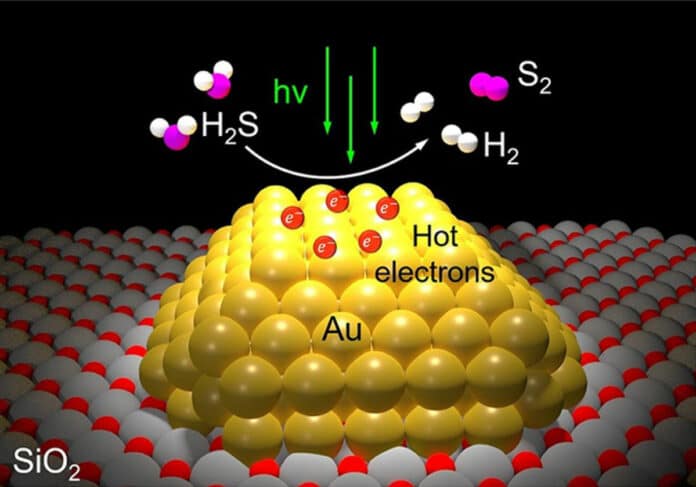

Now, Rice engineers have developed a method that uses gold nanoparticles to convert hydrogen sulfide into high-demand hydrogen gas and sulfur in a single step. The one-step process gets all its energy from light.

“Hydrogen sulfide emissions can result in hefty fines for industry, but remediation is also very expensive,” said Halas, a nanophotonics pioneer whose lab has spent years developing commercially viable light-activated nanocatalysts. “The phrase ‘game-changer’ is overused, but in this case, it applies. Implementing plasmonic photocatalysis should be far less expensive than traditional remediation, and it has the added potential of transforming a costly burden into an increasingly valuable commodity.”

In the new study, the team dotted the surface of grains of silicon dioxide powder with tiny islands of gold. Each island was a gold nanoparticle about 10 billionths of a meter across that would interact strongly with a specific wavelength of visible light. These plasmonic reactions create “hot carriers,” short-lived, high-energy electrons that can drive catalysis.

For their study, Halas and team used a laboratory setup and showed a bank of LED lights could produce hot carrier photocatalysis and efficiently convert hydrogen sulfide into hydrogen and sulfur. It could be a promising alternative to the industrial Claus process that produces sulfur but no hydrogen, which it instead converts into water. Also, the Claus process required multiple steps, some of which required combustion chambers heated to about 1,500 degrees Fahrenheit.

Halas said the plasmonic hydrogen sulfide remediation technology could wind up having low enough implementation costs and high enough efficiency to become economical for cleaning up nonindustrial hydrogen sulfide from sources like sewer gas and animal wastes.

“Given that it requires only visible light and no external heating, the process should be relatively straightforward to scale up using renewable solar energy or highly efficient solid-state LED lighting,” she said.

Journal reference:

- Minghe Lou, Junwei Lucas Bao, Linan Zhou, Gopal Narmada Naidu, Hossein Robatjazi, Aaron I. Bayles, Henry O. Everitt, Peter Nordlander, Emily A. Carter, and Naomi J. Halas. Direct H2S Decomposition by Plasmonic Photocatalysis: Efficient Remediation plus Sustainable Hydrogen Production. ACS Energy Letters, 2022; DOI: 10.1021/acsenergylett.2c01755