Currently, LFP (lithium iron phosphate), NCM, and NCA are three types of power batteries that are used in the majority in the electric car industry. While we await the arrival of solid-state batteries, intermediate steps such as semi-solid-state batteries are arriving, with important advantages in terms of performance, stability, and costs.

Swiss battery manufacturer Leclanché announced that it had achieved a breakthrough in the environmentally friendly production of modern G/NMCA cells. The “G” stands for the graphite in the anode, and NMCA is for a cathode based on nickel-manganese-cobalt-aluminum oxide.

The company is able to reduce the cobalt content in NMCA as cathode material from 20 to 5% and manufacture electrodes using an environmentally friendly water-based process, and increase the nickel content to around 90%. These significant changes in the chemical composition of their cells have allowed these new batteries to have a higher energy density than a ternary lithium-ion cell with similar dimensions and enable a significant reduction in the cobalt content by 15%. At the same time, it also offers a longer service life, high cycle stability, and good charging ability.

In the process, Leclanché completely eliminates the use of N-Methyl-2-pyrrolidone (NMP) as a solvent. This highly toxic organic solvent is what most batteries have to use in the production process.

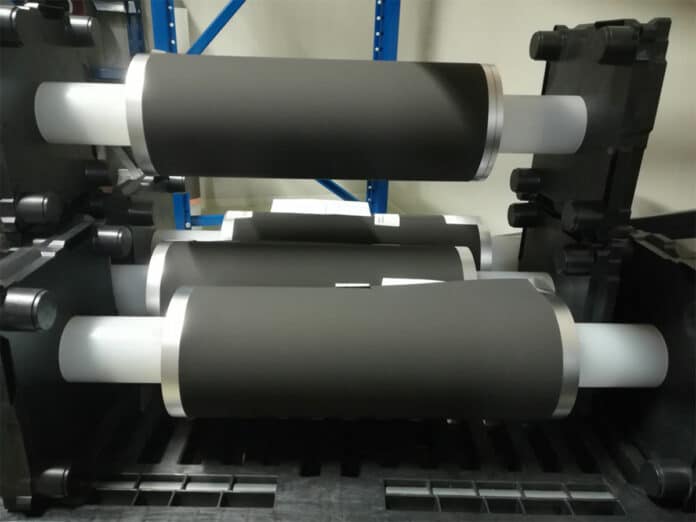

Leclanché, on the other hand, has been using aqueous binders in its manufacturing process for around 13 years. No organic solvents are used in the technically simpler process. This not only eliminates the risk of explosion – there is also no health risk for employees in the production process.

According to the company, the new G/NMCA cells from Leclanché have a 20% higher energy density – with the same size, weight, and performance level – as a Li-ion cell compared to conventional G/NMC cells.

Additionally, thanks to the water-based process, Leclanché can do without energy-intensive processes for drying, flashing off, and recycling the solvents. Thanks to the 10 to 30% lower energy consumption, the Leclanché process also improves the CO2 footprint of battery cell production. Thus, it offers not only ecological but also clear economic advantages.

Thanks to the high-volume energy density and high cycle stability, the new cells are said to be particularly well suited for electric cars as well as heavy-duty applications such as ships, buses, and trucks.

“With the water-based production of the high-capacity NMCA cathodes, we have reached a decisive milestone in lithium-ion technology,” emphasizes Dr. Hilmi Buqa, Vice President of R&D at Leclanché. “Until now, producing them using environmentally friendly processes was considered impossible. But, now we have mastered the process.”

Leclanché’s new environmentally friendly G/NMCA cells are expected to be available on the market in 2024.