High-powered lasers are used in a variety of areas, including industry, medicine, communications, and defense. They are so powerful that it’s difficult to engineer resilient and long-lasting components that can control the powerful beams the lasers emit.

Most mirrors used to direct the beam in high-power continuous wave (CW) lasers are made by layering thin coatings of materials with different optical properties. But if there is even one tiny defect in any of the layers, the powerful laser beam will burn through, causing the whole device to fail.

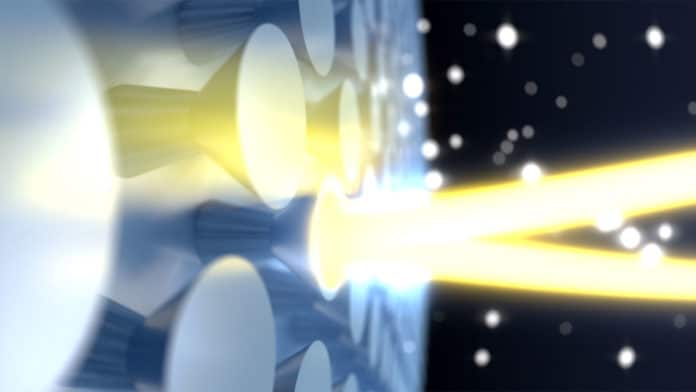

Now, researchers at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) are turning to one of the strongest materials on the planet – diamond – to build a highly reflective mirror that can endure laser beams strong enough to burn through steel. The new type of mirror greatly reduces the chance of defects as it is made from a single material and should also have a significantly longer lifespan due to the strength of the material.

“Our one-material mirror approach eliminates the thermal stress issues that are detrimental to conventional mirrors, formed by multi-material stacks when they are irradiated with large optical powers,” said Marko Loncar, the Tiantsai Lin Professor of Electrical Engineering at SEAS and senior author of the paper. “This approach has the potential to improve or create new applications of high-power lasers.”

To form their new diamond mirror, researchers leveraged a cutting-edge etching technique that was originally used to etch nanoscale structures into diamonds for applications in quantum optics and communications. “We thought, why not use what we developed for quantum applications and use it for something more classical,” said Haig Atikian, a former graduate student and postdoctoral fellow at SEAS.

Using this technique, which uses an ion beam to etch the diamond, the researchers sculpted an array of golf-tee-shaped structures on the surface of a thin diamond sheet measuring just 3 x 3 mm (0.1 x 0.1 in). The shape of the golf tees, wide on top and skinny on the bottom, makes the surface of the diamond 98.9% reflective.

“You can make reflectors that are 99.999% reflective, but those have 10-20 layers, which is fine for low power laser but certainly wouldn’t be able to withstand high powers,” said Neil Sinclair, a research scientist at SEAS and co-author of the paper.

To test their mirror, researchers placed it in front of a 10-kilowatt laser used for the research by the U.S. Navy, which the team says is strong enough to burn through steel. The highly reflective mirror withstood the Navy laser without damage.

“The selling point with this research is that we had a 10-kilowatt laser-focused down into a 750-micron spot on a 3-by-3-millimeter diamond, which is a lot of energy focused down on a very small spot, and we didn’t burn it,” said Atikian. “This is important because as laser systems become more and more power-hungry, you need to come up with creative ways to make the optical components more robust.”

Harvard researchers are exploring the commercialization of the technology. They envision these mirrors being used for defense applications, semiconductor manufacturing, industrial manufacturing, and deep-space communications. The approach could also be used in less expensive materials, such as fused silica.