Shape memory polymers are promising materials in many emerging applications due to their large extensibility and excellent shape recovery. When stretched or deformed, shape memory polymers can be unstretched – resuming their normal state – by applying heat or light. These materials hold great promise for soft robotics, smart biomedical devices, and deployable space structures, but until now, they haven’t been able to store enough energy while being stretched. This means they don’t release much energy while unstretching, which limits their use in tasks that involve lifting or moving objects.

Now, researcher Zhenan Bao at Stanford University in California and her team have developed a shape memory polymer that allows robots to move their arms on their own when the polymers are heated. The new polymers can lift objects 5000 times their own weight and store almost six times more energy than previous versions.

Triggered by heat or light, the new artificial muscle has a polypropylene glycol polymer backbone, to which researchers added 4-,4’-methylene bisphenylurea units. In the original state of the polymer, the material’s chains are tangled and disordered. The stretching caused the polymer chains to align and form hydrogen bonds between the urea groups, creating supermolecular structures that stabilized the highly elongated state. Then, when heated to 70°C, the hydrogen bonds break again, and the polymer can revert to its initial disordered state, releasing energy from the bonds in the process.

In tests, the polymer could be stretched to five times its initial length and store up to 17.9 joules of energy per gram in its extended form – six times that of most other shape-memory polymers.

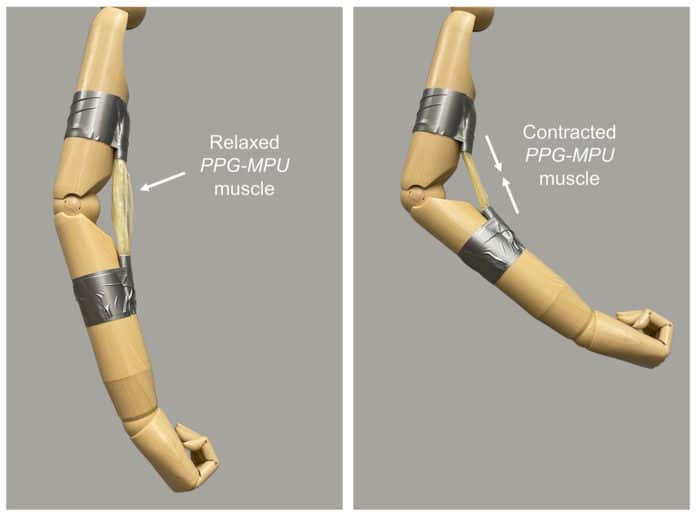

To demonstrate its potential uses, the team also made an artificial muscle by attaching the pre-stretched polymer to the upper and lower arm of a wooden mannequin when heated, the material contracts, causing the mannequin to bend the arm to the height of the elbow.

In addition to its record-breaking energy density, the shape-memory polymer is also inexpensive: the raw materials to manufacture it cost about $11/lb, and the manufacturing process is simple, the researchers say.