Small electric planes are already taking place in the airspace, and so-called flying taxis, eVTOL aircrafts, which can take off and land vertically, are ready to offer new mobility as soon as the legislators give the green signal. Currently, aircraft manufacturers and engine developers are working on one of the most sensitive factors: the mass of the aircraft (especially, the focus is on the batteries).

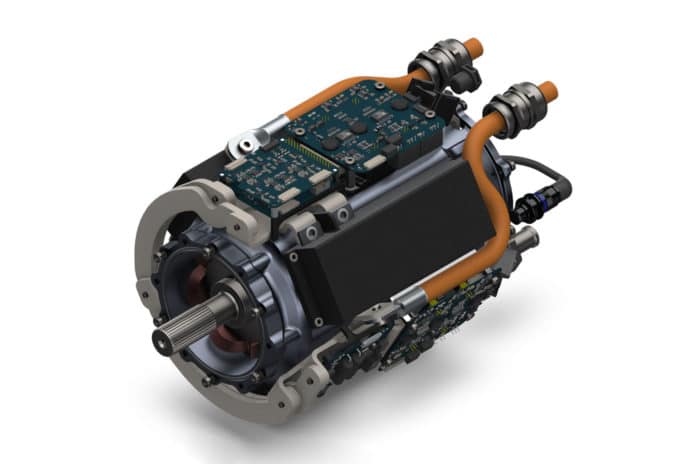

In that regard, an interesting step seems to have been taken in Minnesota. There, the Minneapolis-based startup H3X Technologies seeks to design an electric motor as powerful as those currently produced but at a third or less of the total weight. Called the H3X HPDM-250, it is an ultra-high power density integrated motor drive for electric aircraft.

It combines the electric motor and inverter (+ optional gearbox) into one powerful unit. The electric drive weighs 15 kg and can produce 200 kW of continuous power, with a peak of up to 250 kW. That’s 13.3 continuous kW/kg, an extraordinary power density. For comparison, the engine that ZeroAvia uses in the world’s first commercial hydrogen-powered aircraft, for example, the Magni500 from Magnix, has a power density limited to 4.2 kW/kg.

To achieve such results on the H3X HPDM 250, the researchers optimized the electromagnetic system. The company has developed a new kind of stator coil that is additively manufactured using pure copper with more than 93% IACS conductivity. The AMcoils achieve about 70% copper fill factor in the HPDM-250 and offer a 40% improvement over conventional windings in terms of maximum continuous current density.

The engineers explain that they have also developed a cooling system capable of handling both the power electronics and the engine itself. In addition, while 3D printing of copper coils is a key part of increasing density, they also play an important role in cooling.

The H3X engine runs most efficiently at 20,000 pm. As the speed exceeds the rotation of the propeller, the HPDM-250 can also equip you with an integrated planetary gearbox with a 4: 1 reduction ratio, incurring a weight cost of just three additional kilos. The combined maximum efficiency of the H3X HPDM-250 between the engine, gearbox, and inverter in this configuration is 92.9%.

It is a step-change in electric propulsion technology and removes one of the main barriers blocking the widespread commercialization of electric aircraft. In the future, the H3X Technologies intends to see its engine fitted to small electric planes and multirotor aircraft, such as future flying taxis. It also predicts the arrival of electrification of commercial airliners by 2030.