The noise of aircraft engines not only causes discomfort to passengers but also negatively affects the health of animals. Now, researchers at the University of Bath have developed the graphene-based aerogel, an incredibly light new material that can reduce aircraft engine noise and improve passenger comfort.

This new extremely low-density graphene oxide-polyvinyl alcohol aerogel weighs just 2.1 kg per cubic meter, making it the lightest sound insulation ever manufactured. According to calculations, such a material could be used as insulation within aircraft engines to reduce noise by up to 16 decibels – reducing the 105-decibel roar of a jet engine taking off to a sound closer to that of a hair-dryer.

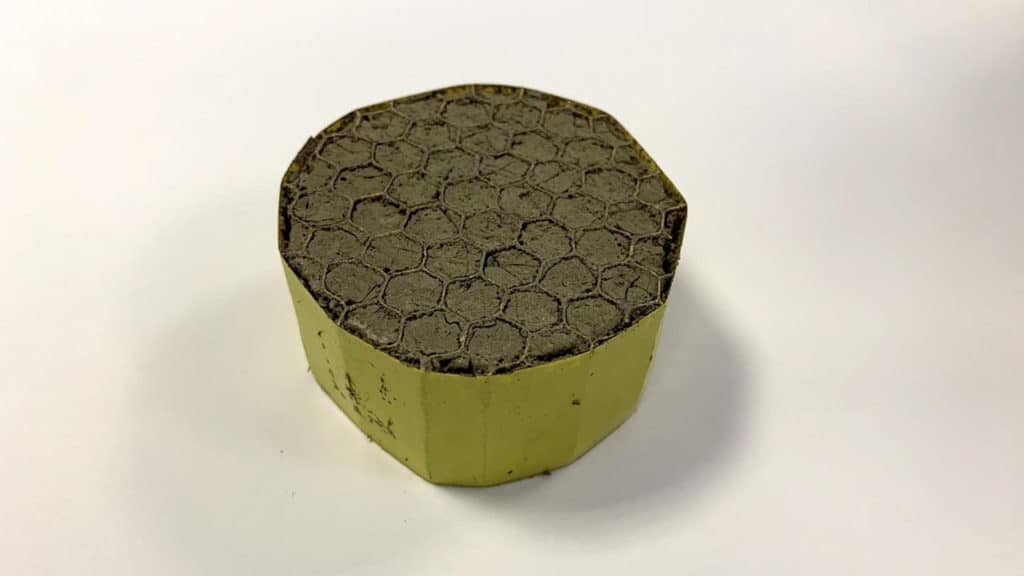

The meringue-like structure of the aerogel makes it extremely light. This means it could act as an insulator within aircraft engine nacelles, with almost no increase in overall weight. Currently, the research team is trying to further optimize this material in order to improve its heat dissipation. This will prevent the material from overheating when working near the aircraft engine, offering fuel efficiency and safety benefits.

“This is clearly a very exciting material that could be applied in a number of ways – initially in aerospace but potentially in many other fields such as automotive and marine transport, as well as in building and construction,” says professor Michele Meo, who led the research.

“We managed to produce such an extremely low density by using a liquid combination of graphene oxide and a polymer, which are formed with whipped air bubbles and freeze-casted. On a very basic level, the technique can be compared with whipping egg whites to create meringues – it’s solid but contains a lot of air, so there is no weight or efficiency penalty to achieve big improvements in comfort and noise,” he continues.

Researchers initially focused on working with aerospace partners to test the material as sound insulation, but their development could also be used for the same function in helicopters or car engines. They believe the thin and light aerogel-based materials will also possess other functional properties such as fire resistance and EMI shielding and will prove to be novel acoustic materials for advanced engineering applications. The aerogel could be commercialized and in use within 18 months.