The U.S. Air Force and General Electric (GE) have begun the Phase 2 testing of GE’s second XA100 adaptive cycle engine at the Air Force’s Arnold Engineering Development Complex (AEDC) in Tennessee.

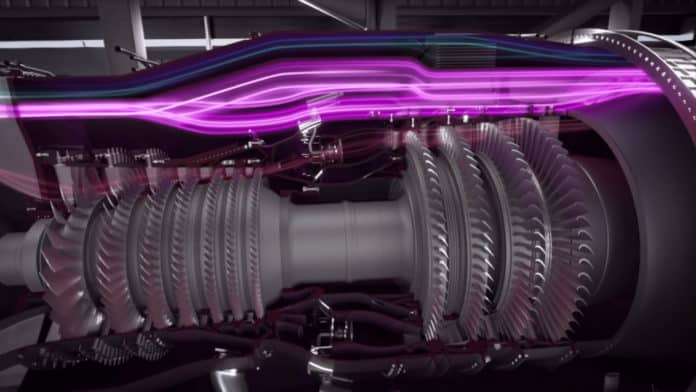

The Phase 1 testing of this XA100 engine was completed in November 2021 in Evendale, Ohio. Developed by GE Edison Works advanced program unit, the XA100 is a three-stream adaptive cycle engine demonstrator that can direct air to the bypass third stream for increased fuel efficiency and cooling or to the core and fan streams for additional thrust and performance.

GE’s XA100 engine is uniquely designed to fit both the F-35A and F-35C without any structural modifications to either airframe, enabling better aircraft range, acceleration, and cooling power to accommodate next-generation mission systems, while also ensuring durability and enhanced readiness.

“The XA100 simultaneously provides transformational improvements in fuel efficiency, thrust, power, and thermal management that simply cannot be matched by legacy propulsion systems,” said David Tweedie, GE Edison Works’ general manager for Advanced Combat Engines. “These improvements will help ensure the F-35 remains a preeminent fighter platform not just in the near-term, but for decades into the future, and will enable lower operational and sustainment costs for the services.”

GE’s engine became the world’s first-ever flight-weight, three-stream adaptive cycle engine in December 2020 before initiating tests on its second engine in August 2021.

The adaptive engine cycle provides both a high-thrust mode for maximum power and a high-efficiency mode for optimum fuel savings and loiters time. The engine’s three-stream architecture provides a step-change in thermal management capability, enabling future mission systems for increased combat effectiveness. Moreover, the engine also uses new heat-resistant materials such as ceramic matrix composites (CMC) to enable higher turbine temperatures and improved performance.

According to GE, these revolutionary innovations increase thrust by more than 10%, improve fuel efficiency by 25%, and provide significantly more aircraft heat dissipation capacity. In addition, the XA100’s improved fuel efficiency provides a significant reduction in carbon emissions and will operate on any U.S. Air Force-approved Sustainable Aviation Fuel.

The XA100 is a product of GE Edison Works, a business unit dedicated to the research, development, and production of advanced military solutions. This business unit has full responsibility for strategy, innovation, and execution of advanced programs.