In the electronics industry, successfully securing several layers of components on top of each other to make complex devices is a challenging task. Getting these layers to stick together can be a frustrating process, particularly for printed electronics. Also, most inks rely on environmentally harmful solvents for solubilizing and postprint processing of the nanomaterials.

Now, Duke University engineers have produced the world’s first fully recyclable printed electronics that replace the use of chemicals with water in the fabrication process. Bypassing the need for hazardous chemicals could reduce the industry’s environmental footprint and human health risks.

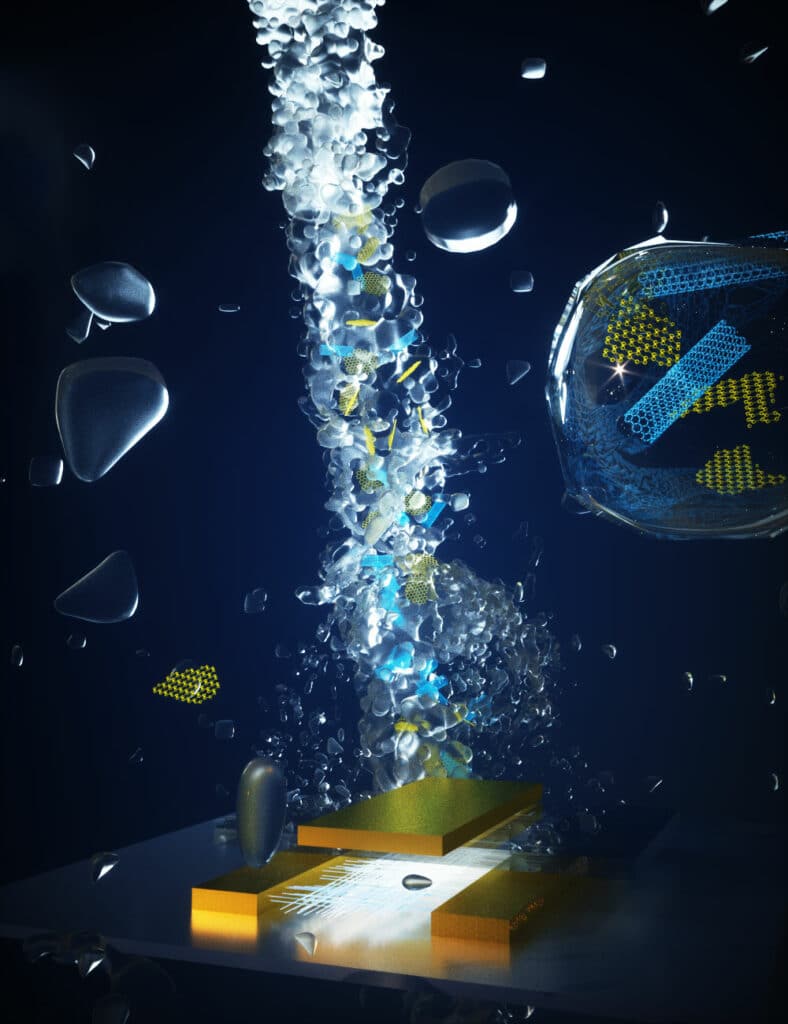

Previously, researchers demonstrated the first fully recyclable printed electronics. The devices used three carbon-based inks: semiconducting carbon nanotubes, conductive graphene, and insulating nanocellulose. The carbon nanotubes presented the largest challenge in an attempt to adapt the original process to only use water.

To make a water-based ink in which the carbon nanotubes don’t clump together and spread evenly on a surface, researchers added a surfactant similar to detergent. However, the resulting ink does not create a layer of carbon nanotubes dense enough for a high current of electrons to travel across.

“You want the carbon nanotubes to look like al dente spaghetti strewn down on a flat surface,” said Aaron Franklin, the Addy Professor of Electrical and Computer Engineering at Duke. “But with water-based ink, they look more like they’ve been taken one by one and tossed on a wall to check for doneness. If we were using chemicals, we could just print multiple passes again and again until there were enough nanotubes. But water doesn’t work that way. We could do it 100 times, and there’d still be the same density as the first time.”

This happens because the surfactant used to keep the carbon nanotubes from clumping also prevents additional layers from adhering to the first. In a traditional process, these surfactants would be removed using either very high temperatures or harsh chemicals, which can pose human and environmental health risks.

To avoid both, Franklin and his team developed a cyclical process in which the device is rinsed with water, dried in relatively low heat, and printed on again. When the amount of surfactant used in ink is also reduced, researchers show that their inks and processes can create fully functional, fully recyclable, fully water-based transistors.

Franklin has already proven that nearly 100% of the carbon nanotubes and graphene used in printing can be recovered and reused in the same process. Nanocellulose is made from wood and can simply be recycled or biodegraded like paper. Although the process does use a lot of water, it’s less than what is required to deal with the toxic chemicals used in traditional fabrication methods.

While more work needs to be done, Franklin says the approach could be used in the manufacturing of other electronic components like the screens and displays that are now ubiquitous to society. By demonstrating a transistor first, he hopes to signal to the rest of the field that there is a viable path toward making some electronics manufacturing processes much more environmentally friendly.

“The performance of our thin-film transistors doesn’t match the best currently being manufactured, but they’re competitive enough to show the research community that we should all be doing more work to make these processes more environmentally friendly,” Franklin said.

Journal reference:

- Shiheng Lu, Brittany N. Smith, Hope Meikle, Michael J. Therien, and Aaron D. Franklin. All-Carbon Thin-Film Transistors Using Water-Only Printing. Nano Letters, 2023; DOI: 10.1021/acs.nanolett.2c04196