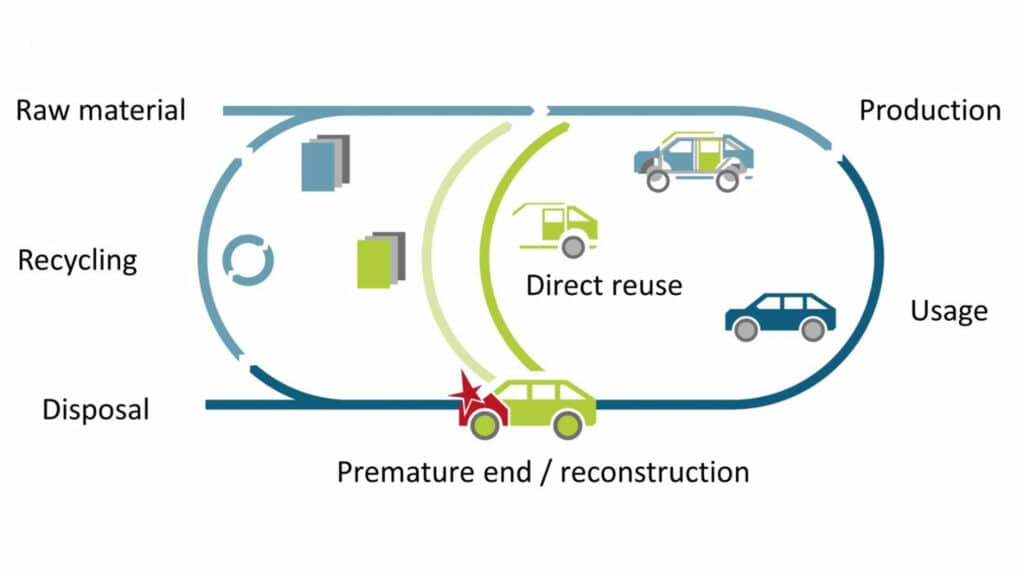

Currently, used cars and cars involved in accidents are often disposed of via energy-intensive scrapping processes, even if many parts are still functional.

In Germany, Fraunhofer researchers in the EKODA project (Efficient and Economic Cycle-Oriented Dismantling and Reconditioning) aim to develop a better alternative to scraping used cars. The team of researchers is developing and optimizing an evaluation system that enables the optimal reuse of electric vehicle parts before recycling.

The software, which is equipped with AI algorithms, is one of the core technologies of the EKODA project. It aims to bring about a circular economy through efficient, economically viable disassembly and processing.

According to the researchers at Fraunhofer IWU, all the components are examined first in a complex test procedure. An evaluation system then gives recommendations on how the components could be reused. With the consideration and analysis of the individual components, nothing less than the classic recycling of the entire system should be replaced, according to the declared goal.

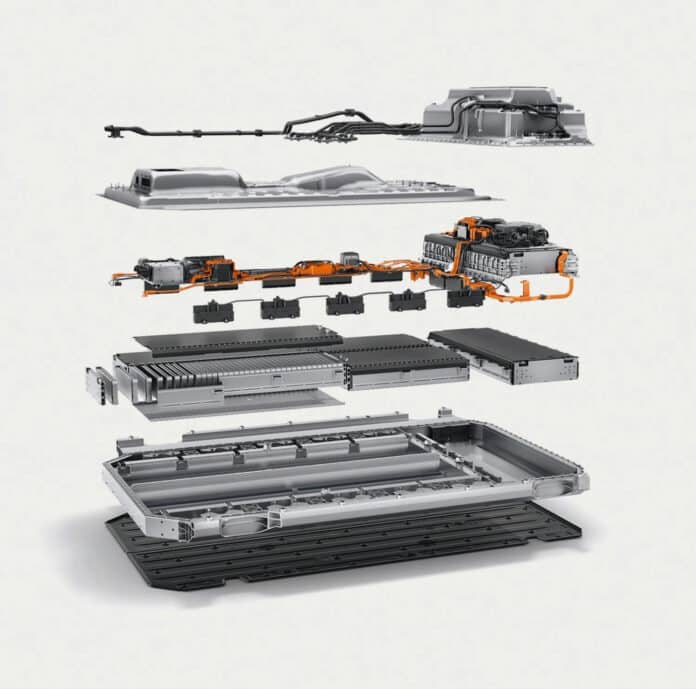

The concept optimizes the service life of the individual parts and enables the development of a sustainable circular economy in the field of mobility. Batteries, transmission shafts, or gears could also end up in applications outside of the automobile. The core tasks of the EKODA project include the dismantling and analysis of parameters such as performance, state of charge, and functionality in the battery area.

The camera system first records the type, model, serial number, and power class (in kilowatts) and the serial number of the battery pack removed from a used or crashed car and compares them with an internal database. In the next step, the battery cover is removed semi-automatically. Further analyzes follow so that a measuring system records the current state of charge, the functionality of the control electronics, and the condition of the individual battery cells.

The evaluation software developed by the Fraunhofer IWU uses the data to create a detailed condition profile, analyzes it, and makes recommendations for further use. For example, an intact battery in good condition could therefore be transferred in a used car, while an older energy storage device could be used in a “smaller agricultural machine,” according to the institute. If several cells are defective, the battery could still be suitable for stationary use, for example, as an electricity storage device for a photovoltaic system in your own home.

The same principle of examination and reuse can be applied to other car parts too. “We want to move away from traditional recycling, instead looking at every component of a car as a valuable resource – regardless of the function they currently serve in the vehicle. This is why we are working on a strategy for testing whether these individual components can be reused or repurposed in various contexts,” explains Dr. Uwe Frieß, head of the department for body construction, assembly, and disassembly at Fraunhofer IWU.

Researchers are also working on processes for automatically disassembling the individual components. By implementing this strategy systematically, they hope to enable the reuse of all components as part of a circular economy. The Chemnitz-based researchers are not only analyzing battery storage systems – they are also focusing on parts such as the car body and the drive train. Some parts of the drive train, such as shafts or cogwheels made of metal or steel, could also be suited for remanufacturing.

“The evaluation system that we are building is designed to be complex and holistic. Ecological criteria will be given the same weight as technological and economic factors, such as CO2 emissions and energy consumed during repurposing, for example,” explains Patrick Alexander Schmidt, a researcher at Fraunhofer IWU. “The evaluation system will also take into account fluctuations in electricity prices in a dynamic way, based on the relevant daily figures,” promises Mr. Schmidt.